How the 4M Method Can Improve Your Manufacturing Operations

By Yangjin Yoon

Many leading operations managers use the 4M Method to organize their challenges into discrete, solvable pieces. In doing so, they make prioritizing and solving those problems much simpler.

Trying to find the root cause of production issues can be overwhelming. Modern manufacturing is a complex mechanism made up of elements that unpredictably impact each other.

The 4M Method can also make implementing lean manufacturing concepts like Continuous Improvement much easier and more effective.

Ready to learn more, and find out what’s up with the fish in the image? Let’s dive in.

Origins of the 4M Method

The 4M Method, much like Continuous Improvement, has its roots in Japanese manufacturing and organization theory.

Kaoru Ishikawa was a professor at Tokyo University who translated and taught the concepts of American management theorists like W. Edwards Deming (a founder of Continuous Improvement thinking) and Joseph Juran.

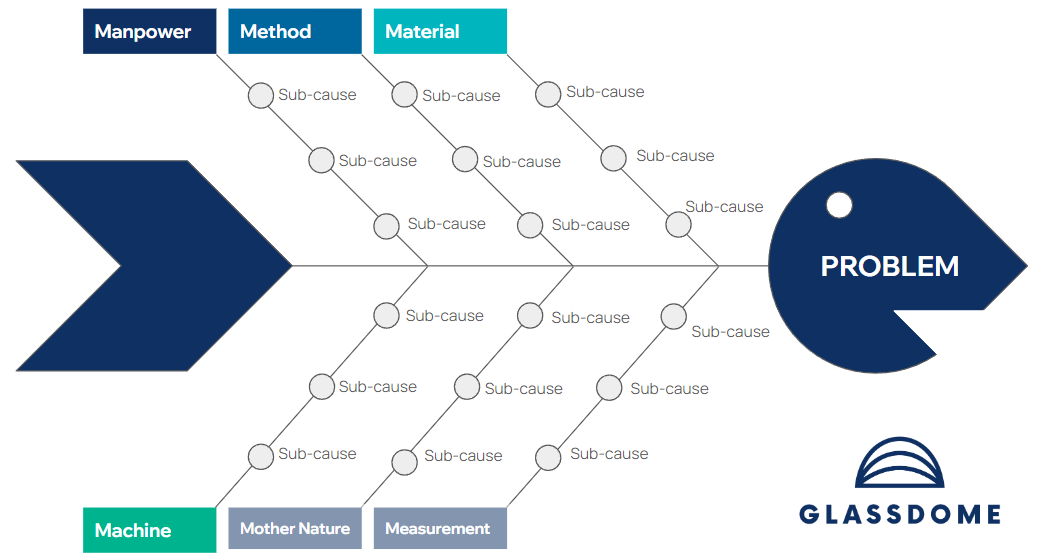

Ishikawa wanted to determine how to apply continuous improvement to processes when all variables are known. The result was the fishbone diagram (initially composed of 6Ms) shown below, out of which the 4M Method emerged.

What is the 4M Method?

The 4M Method is a way to identify and group the causes of a specific problem or effect in a manufacturing process. The four factors most manufacturers use are Manpower, Method, Material, and Machine.

Manpower

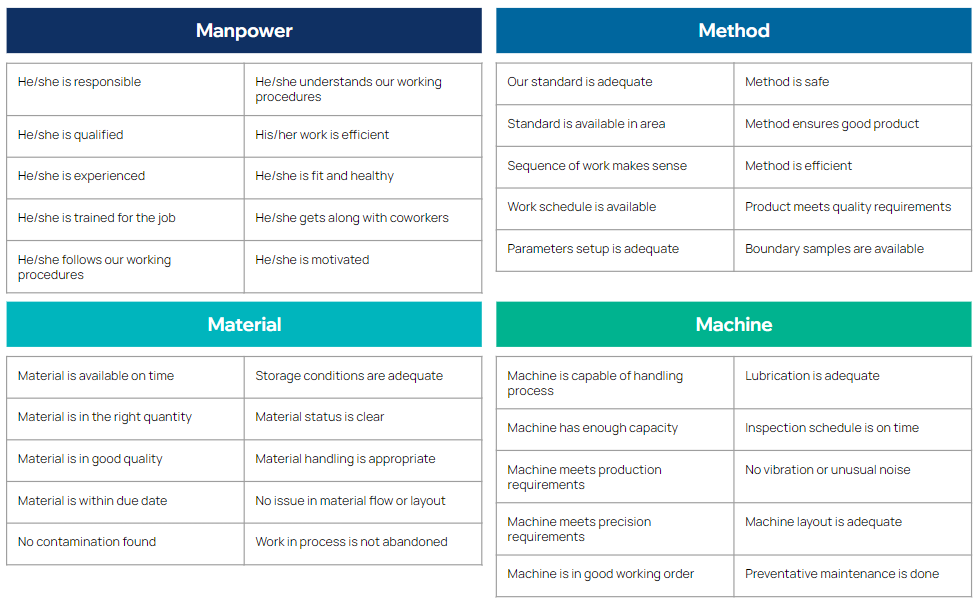

This M is about all things people – skills, operations, and resources. Common issues grouped under Man include: Lack of skills, missing qualifications, inadequate training, poor habits and behavior, and lack of motivation.

To apply the Manpower factor (yes, it sounds like a deodorant brand) to current performance, companies should:

- Organize training opportunities to improve employees’ qualifications and skills.

- Define the capabilities of each employee, identify their strengths and weaknesses, and ensure they are in the best position to succeed

To apply the Manpower factor to the future, companies should:

- Rigorously define job goals and performance indicators

- Invest in recruiting the best team members in both ability and attitude, whether through pay or other benefits

The ultimate question we need to answer is: Do my employees have the skill and the will to do what is expected of them safely, consistently and effectively?

Method

Method means the way you do things – processes, schedules, and procedures. Common issues grouped under Method include: Inadequate procedures, instructions, specifications, or responsibilities, incorrect process definitions, or not applying best production practices

To apply the Method factor to current performance, companies should:

- Create a clear production strategy with public goals and metrics, and identify tasks that will help achieve those goals

- Make sure each employee and department has tasks that match their skills and goals

- Use a software solution for visibility, analysis, and informed decision making

To apply the Method factor to the future, companies should:

- Review the percentage of errors (whether that is reflected in quality or production amount) when they apply their methods

- Ensure their security is top-notch

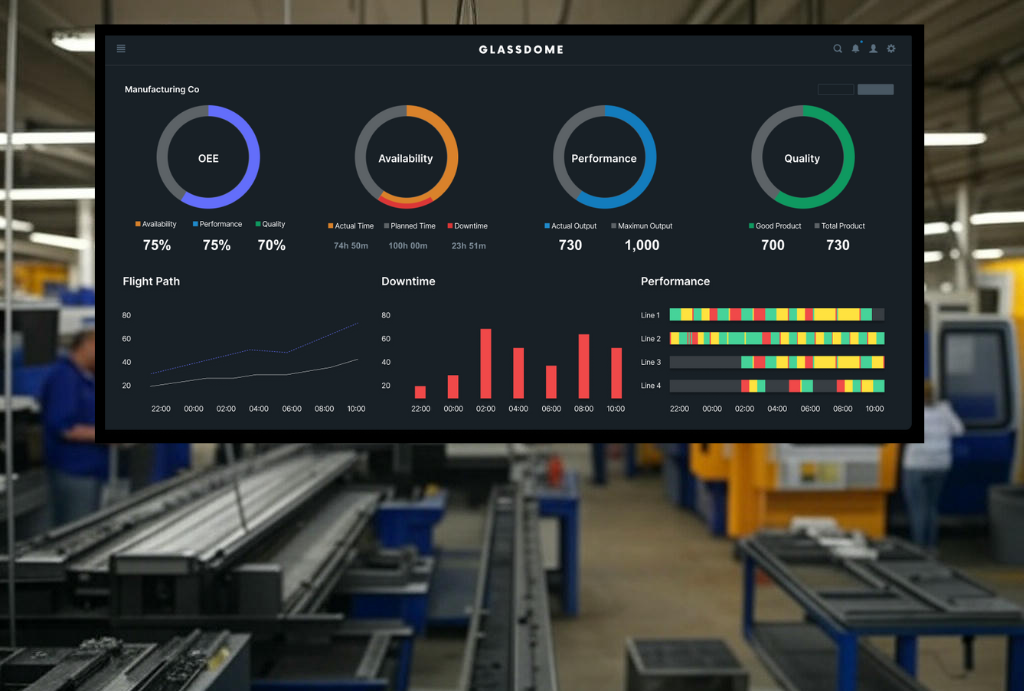

- Build charts and dashboard to track progress (Glassdome’s CI solution is great at creating custom dashboards)

- Review instructions for machine operation, and place them where employees can easily review them

The ultimate question we need to answer is: Do I have the processes in place to produce my products consistently and safely?

One real life example: A Glassdome confectionary client measured quality by pulling snacks off of the conveyor belt by hand, measuring them with calipers, writing down the information, and handing the completed sheet to operations staff at the end of the day.

If there was a machine fault, hundreds of out-of-tolerance snacks could be produced before the problem was spotted and fixed.

By installing the Glassdome Product Monitoring solution and automating the method with real-time data collection, the quality issues were dramatically reduced.

Once Glassdome was installed, the quality control measurer was reassigned to manage machines.

In this case, a Method fix helped resolve Machine faults quickly, and optimized Manpower. The 4Ms are all interconnected.

Material

Material means the inputs in your process – information, raw materials and consumables. Common issues grouped under Material include: Poor quality of raw materials, defective components from suppliers, poor storage conditions, sourcing delays or excess

To apply the Material factor to current performance, companies should:

- Rigorously review exactly how many materials they need in their production process

- Check how materials and inventories are handled

- Invest in technology that allows real-time review on quantities and conditions in warehouses

To apply the Material factor to the future, companies should:

- Create or automate a process to check incoming material quality

- Apply just-in-time manufacturing concepts to reduce the amount of raw materials and finished products that need to be stored for long periods of time

- Develop a supplier management system to consistently re-evaluate the caliber of your suppliers

The ultimate question we need to answer is: Do my materials meet my needs? Are there no defects or shortages? Are they being handled or moved too much? Are they stored in the right conditions?

Machine

Machine is simple. It means the equipment you use to make your products. Common issues grouped under Machine include: Inadequate care, cleaning, and inspection, inadequate or aging machines, or poor installation

To apply the Machine factor to current performance, companies should:

- Create a comprehensive maintenance plan that works with your production schedule

- Implement software that helps you see and solve issues with machine maintenance and help you predict over- or under-use of your machines

- Invest in modern machinery. It’s expensive, but just like trading in a creaky lemon for a new car it can be worth it over the long run

To apply the Machine factor to the future, companies should:

- Review their maintenance schedules and results

- Review how machines are arranged on the floor and how and when they’re used for maximum efficiency

- Check that employees are properly assigned to machines based on their skills, and how many operators the machine needs

The ultimate question we need to answer is: Are my machines capable of sale and reliable output at the quality and rate I want? Are breakdowns, defects, or unplanned downtime getting in the way of that goal?

How can I use the 4M Method? And how can Glassdome help?

By prioritizing your issues through the 4M method, you can turn an ominous cloud of problems into a structured plan full of solutions. Making continuous improvement a lot more manageable.

Continuous Improvement is all about making big improvements over time through frequent small wins. It’s a natural fit with the 4M Method’s emphasis on prioritization and visibility.

It can start with a simple checklist like the one below.

Both methodologies only work to their highest potential if you can see and analyze what’s actually happening on your factory floor. That’s where Glassdome’s real-data-based Production Monitoring solution comes in. By seeing real machine, shift, and production data in real time, you can make informed decisions that lead to big improvements.

You’ll cut downtime, increase quality, and solve problems faster.

Sound appealing? Get in touch with one of Glassdome’s manufacturing experts to learn more.