How can the Chemical Industry Decarbonize?

By Glassdome

The chemical industry is one of the major contributors to world greenhouse gas emissions and the world needs it to decarbonize. It is estimated to account for about 8% of world greenhouse gasses emitted by industry. If chemical companies can reduce their emissions, it will play a meaningful role in reducing total global carbon emissions.

30% of emissions in the chemical supply chain are attributed to carbon generated in Scope 1 and Scope 2 (directly by the company, or through the energy required to power its processes). The remaining emissions fall under Scope 3 (they’re created from the rest of the supply chain), particularly from greenhouse gasses emitted during the procurement of raw materials.

That means efforts to reduce Scope 3 emissions are just as, if not more, important than Scope 1 and 2. But getting suppliers and partners onboard is a challenge. Which leads to the big question: how can chemical producers decarbonize?

Together for Sustainability

Many of the world’s largest chemical industry companies are uniting to decarbonize through the Together for Sustainability (TfS) initiative.

TfS is dedicated to raising corporate social responsibility standards throughout the chemical industry and its supply chain. The current membership includes chemical companies with total sales of more than 800 billion euros and total purchasing power of more than 500 billion euros.

TfS issued its first Product Carbon Footprint (PCF) Guidelines in fall 2022. They emphasize the PCF calculation for raw material supply chain partners falling under Scope 3 Category 1 of the GHG Protocol, purchased goods and services. Category 3.1 suppliers are responsible for the highest carbon emissions throughout the entire supply chain.

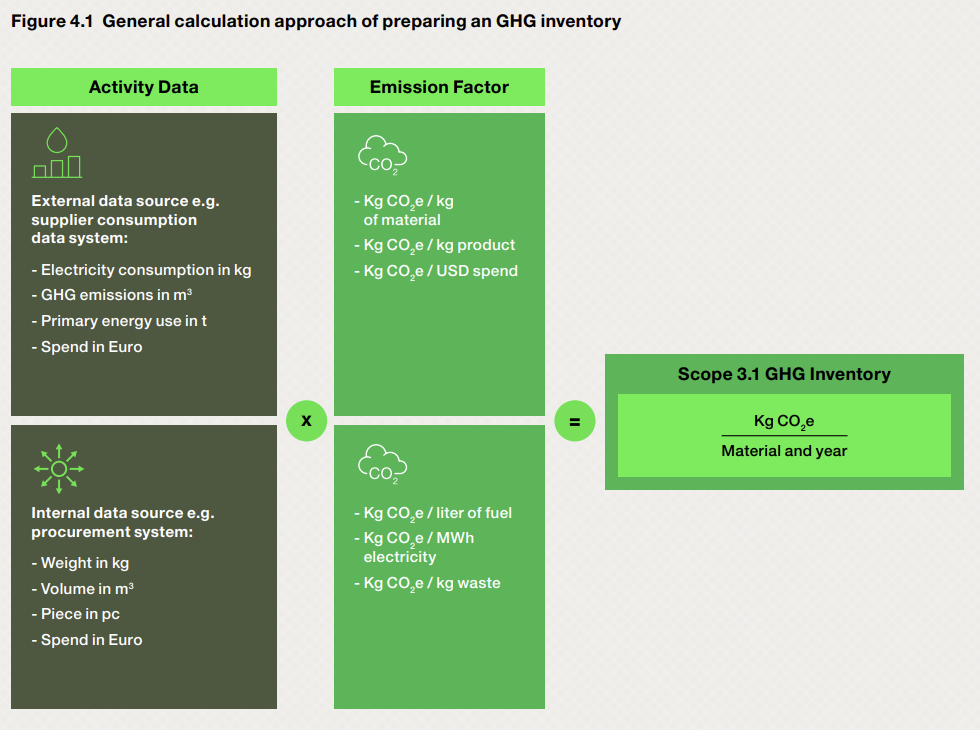

How do TfS companies calculate Scope 3 emissions?

In the past, different companies used different methods to calculate their Scope 3 emissions. The TfS initiative is helping companies and certification agencies (like TÜV Rheinland) work together to establish consistent standards that the entire industry can use.

(Source: TfS PCF Guideline)

The guidelines specify that the Emission Factor of the partner companies can be obtained from the following sources:

- Verified data from associations like ISOPA, Plastics Europe, Fertilizers Europe, or the World Steel Association

- LCA databases like ecoinvent, Carbon Minds, AGRIBALYSE, or EPLCA

- Official national emission factor databases such as the EPA, IEA, Defra, or GREET

- Supplier data

Companies required to submit reports are explicitly instructed to use the most accurate data. To achieve this, TfS recommends that companies establish a data management plan to get consistent primary data. If getting supplier data proves difficult, it recommends focusing on getting primary data from the largest contributors to your carbon footprint and then extrapolating the rest.

TfS recommends using IT tools (like Glassdome) to automate primary data acquisition. But sometimes it’s just not feasible to get primary data directly from suppliers’ processes. In those cases, the use of secondary data, like that obtained from public databases, is acceptable.

However, one of the most important factors in helping the chemical industry to decarbonize will be the reliability of the Emission Factor calculated by Scope 3 partners, as it states that the reliability of the data for calculating the emission factor is subject to evaluation, and in the long term, it is essential to identify which processes contribute the most to carbon emissions to effectively reduce carbon emissions.

What can your chemical company do right now to reduce carbon emissions?

- Put a data management plan in place

- Get accurate data from your own operations

- Work with suppliers to get their accurate primary data

- Use a software platform that can automate data collection and analysis

Put simply, you need to get your own data, then your suppliers’ data, analyze it, and report it back so you can make smart decisions.

Need help getting you and your supplier’s primary data quickly, and getting it verified?

Glassdome can help. Our Continuous Improvement software attaches directly to your production line for primary data extraction. Our PCF solution is ISO 14067 verified, meaning you get actionable results that are designed to be quickly certified in the EU and US. And our expert consultants help you get up and running quickly and stress-free. It’s the smart choice for your company’s future.