EU Battery Regulation: Timeline and System Boundary Requirements

By TJ Yoon

EU Battery Regulation 2023/1542 is a gamechanger for battery makers importing to the EU and the companies they supply and it is on a tight timeline.

We’ve covered what these regulations mean for battery manufacturers in depth in a previous Insight.

In this Insight, we want to focus on the timeline. What do battery manufacturers need to act on for the near term, and what do they need to plan for in the long term?

EU Battery Regulation Overview

Before we start, let’s quickly review what EU Battery Regulation 2023/1542 entails:

Objective:

The EU Battery Regulation aims to ensure that batteries placed on the European market are sustainable and safe throughout their life cycle, covering all actors and their activities.

Who is impacted by the EU Battery Regulation?

The Regulation applies to any battery in the EU market with a capacity over 2kWh

What is required?

Article 7, together with Annex II, dictates required carbon footprints of electric vehicle batteries and rechargeable industrial batteries.

When does it start?

The regulation begins to come into force a year from the passage of its implementing act – likely sometime in 2025.

When do I need my Product Carbon Footprint? How about a digital battery passport?

You need to start with a real-data-based Product Carbon Footprint.

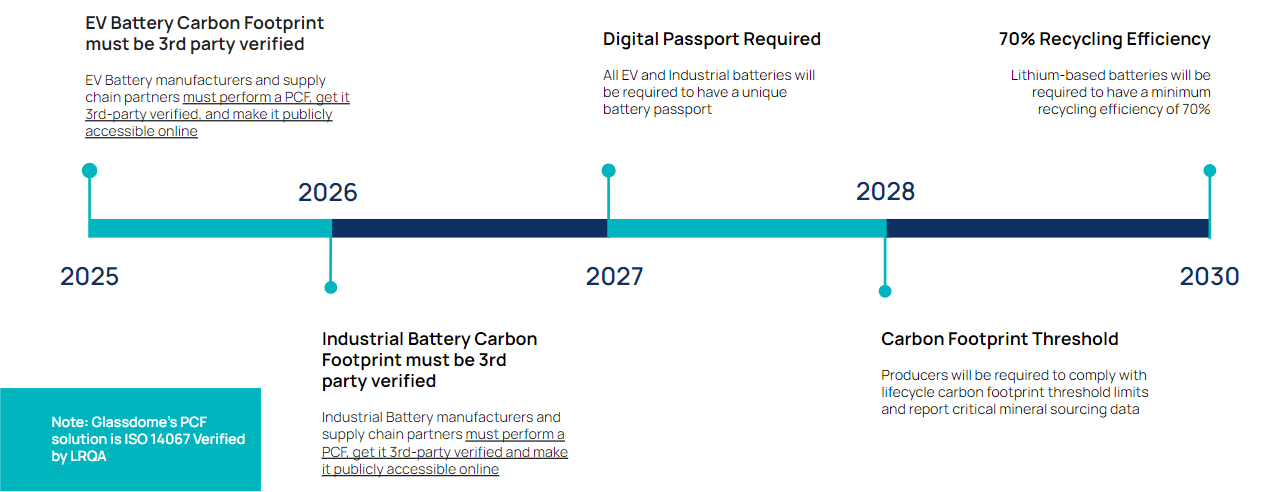

The EU battery regulation timeline requires the carbon footprint of every EV battery sold in the EU be calculated and made publicly accessible by February 2025. Industrial batteries over 2kWh get an extra year – their deadline is in 2026.

The information in the footprint must be specific to each model and manufacturing plant and collected throughout the value chain. Any changes to materials or facility-level energy mix must be reflected, and carbon offsets cannot be included in the calculation. This will be used by the EU to help sort EV batteries into similar-performing types for easy identification in the future.

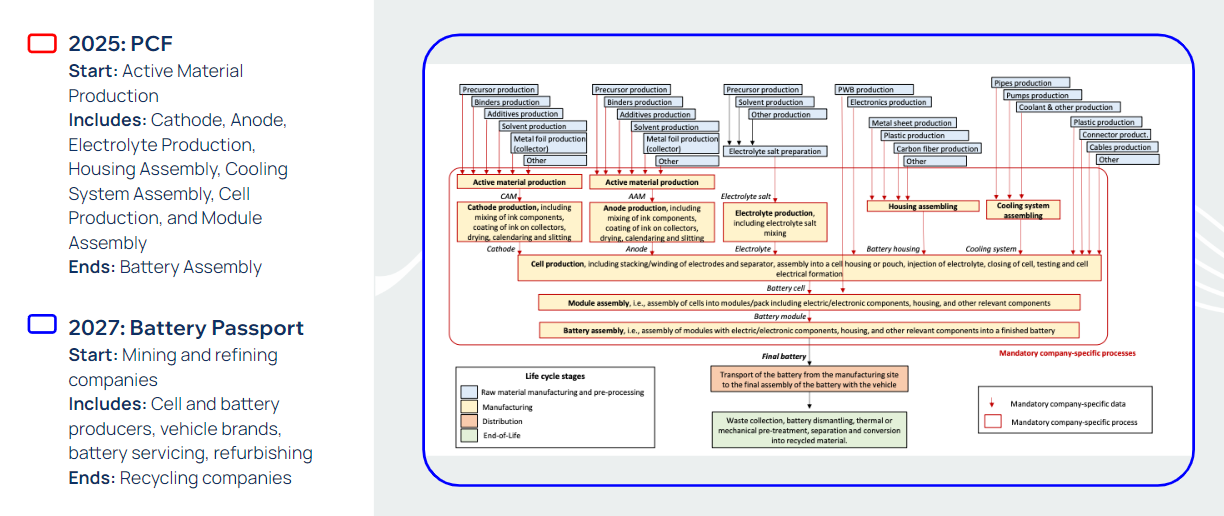

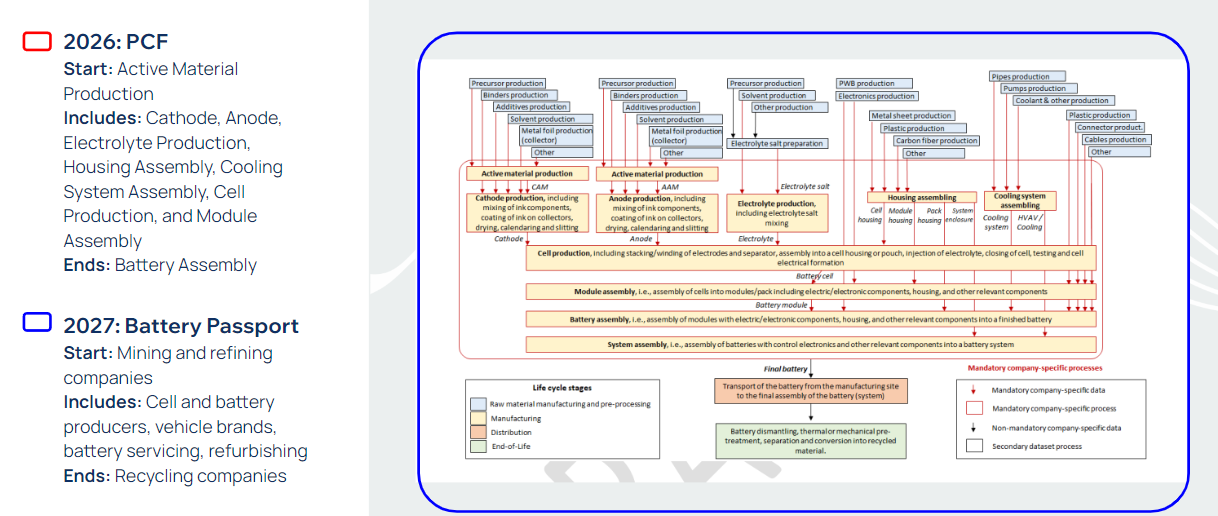

For the 2025 and 2026 deadlines, the Product Carbon Footprint just needs to include active material production. This system boundary, from raw materials to the finished product leaving the factory, is often called Cradle to Gate.

In the medium term, you’ll need to start engaging your suppliers and partners. In 2027, the system boundary requirements will expand to cover the four main stages of the battery life cycle:

- Mineral extraction and pre-processing

- Battery manufacturing (inclusive of active materials, cell manufacturing, and battery pack assembly)

- Distribution

- End-of-life processing and recycling

This full-lifecycle view is called Cradle to Grave.

Check out the infographics below for complete system boundary information.

For EV Batteries:

For Industrial Batteries:

Also in 2027, that data will need to be stored in a publicly available Digital Battery Passport. The idea behind the gap is to give companies time to iron out the process before the repercussions for failure get more serious.

(Already thinking about how much work that plant-level, real data-based PCF is going to be to calculate? Glassdome can help. Our PCF platform makes Battery Regulation compliance simple.)

Where should I start?

You should have all of the digital and organizational infrastructure in place to respond as soon as the implementing act is a go.

The most immediate need is a Product Carbon Footprint for each EV and industrial battery you produce. Then you can incorporate that PCF into a Digital Battery Passport.

Step 1: Calculate your PCF

As you can probably gather from the diagrams above, PCF calculation can be incredibly tedious and time-consuming. Setting your system boundaries, poring through dense databases, making sure you’re complying with reams of certification and legal regulations. Glassdome’s PCF solution helps manufacturers simplify PCF calculation and reporting.

Step 2: Verify your PCF

Not just any PCF report will do when you’re trying to comply with regulations. You need to create a report that complies with international standards to achieve your business needs. Glassdome’s PCF solution is ISO 14067 verified by LRQA. That means you’ll be able to get the PCF report you create with Glassdome verified quickly and easily compared to competitor solutions.

Step 3: Publish your PCF

Create a publicly available platform for regulators and customers to view your PCF. Our consultants can help ensure you’re complying with EU regulations.

Step 4: Create your Digital Battery Passport

With a compliant PCF in place, you have a couple of years to build the infrastructure of a digital battery passport for all of your battery models. Glassdome’s plant and product level data makes acquiring real data across multiple models a snap.

Want to learn more? Get in touch with a Glassdome sustainability expert today.

Through our work with organizations like Samsung SDI, the Global Battery Alliance, and LG Electronics, we know how to help the world’s leading battery makers prepare for this regulation.