Technical Guide: How to Configure MTConnect on a Haas NGC Controller

By Jordan Cota

Need to configure MTConnect on a Haas NGC controller? You’re in the right place.

MTConnect is a standard vocabulary that allows users to capture and share manufacturing data in real time. On Haas machines with the Next Generation Control (NGC), MTConnect lets you access status information, equipment metadata, and historical data using a simple HTTP-based Request/Response model outputting XML. By following the steps in this guide, you can set up MTConnect and verify its functionality on your Haas NGC machine.

Note: Most Haas Controllers (NGC) created after 2017 support this MTConnect option

Recommended Software: For advanced data monitoring and analysis, consider the Glassdome Production Monitoring software solution. Glassdome can help visualize machine status, track performance metrics, and boost operational efficiency. We will break down some examples of how Glassdome can use this real-time data for live reporting later.

1. Check Machine Requirements

Software Version

Confirm that your Haas NGC controller is running software version 100.20.000.1200 or newer. This ensures the best compatibility with MTConnect.

Machine Naming

If your machine’s name contains a slash ‘/’, you may need an additional patch for MTConnect to work correctly. Contact your local Haas Factory Outlet if this applies.

2. Understand MTConnect Requests

MTConnect on Haas NGC uses an HTTP-based approach where a client (e.g., monitoring software) sends a Request, and the Haas machine’s MTConnect Agent (server role) returns a Response.

There are three primary MTConnect requests:

Probe Request

- Retrieves machine metadata, including descriptions of data points.

- http://172.21.16.31:8082/probe

Current Request

- Fetches the latest (real-time) values of each data point.

- http://172.21.16.31:8082/current

Sample Request

- Requests historical data from a specified range of sequence numbers.

- http://172.21.16.31:8082/sample

3. Configure MTConnect on Haas NGC

Connect the Machine to Your Network

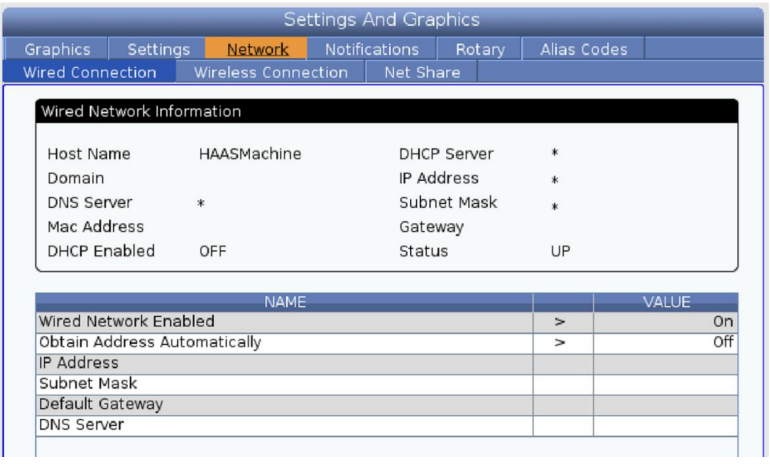

From the Haas controller, navigate to Settings > Network > Wired Connection.

If your machine already has an IP Address, Subnet Mask, and Gateway IP, record this information, and make sure Wired Network Enabled has a value of ‘On’

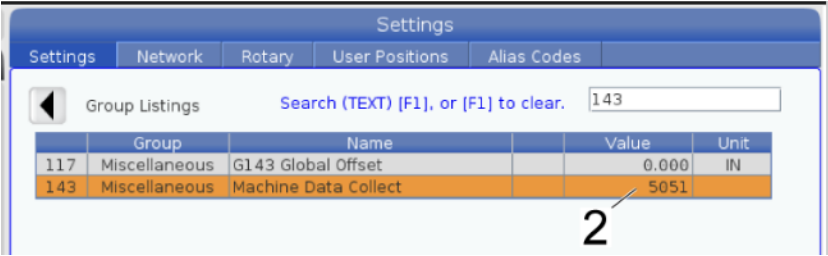

Confirm Setting 143 ‘Machine Data Collect’ port is set to 5051 and press F4 to save

The network status should be “UP” (active). If it shows “DOWN,” confirm that cables or wireless connections are properly set up.

If this information is blank, complete the following steps: ON THE “WIRED CONNECTION”

- Enter a suitable IP, Subnet, and Gateway

- Make sure ‘Wired Network Enable’ is ‘ON’, and ‘Obtain Address Automatically’ is ‘OFF’

- Save changes by pressing F4

- Record the IP Address:, Gateway, and the Subnet of your machine save these values by Photo or written notes

- Set Setting 143 ‘Machine Data Collect’ port to ‘5051’ by Navigating to the “Settings” header (see figure “2” on the image below) press F4 to save

Confirm the MTConnect Port is allowed by your network

Haas NGC will use TCP port 5051 internally (Adapter) for MTConnect after you have set it.

Ensure no firewall or other service is blocking traffic on TCP port 8082 (Agent).

You can connect to the local subnet and test this port from the ‘command prompt’ on your PC

4. Construct MTConnect Request URLs

MTConnect requests generally follow this format:

http://<machine_ip>:8082/<request_type>

- machine_ip: The IP address of your Haas machine (e.g., 172.21.16.31).

- machine MTConnect Agent: port 8082

- request_type: One of probe, current, or sample.

Note: Glassdome primarily uses the “Current” request type for real-time data retrieval.

5. Test and Verify MTConnect

Use a Web Browser or HTTP Client

- Type the MTConnect request URL into a web browser (Chrome, EDGE, Firefox etc.)

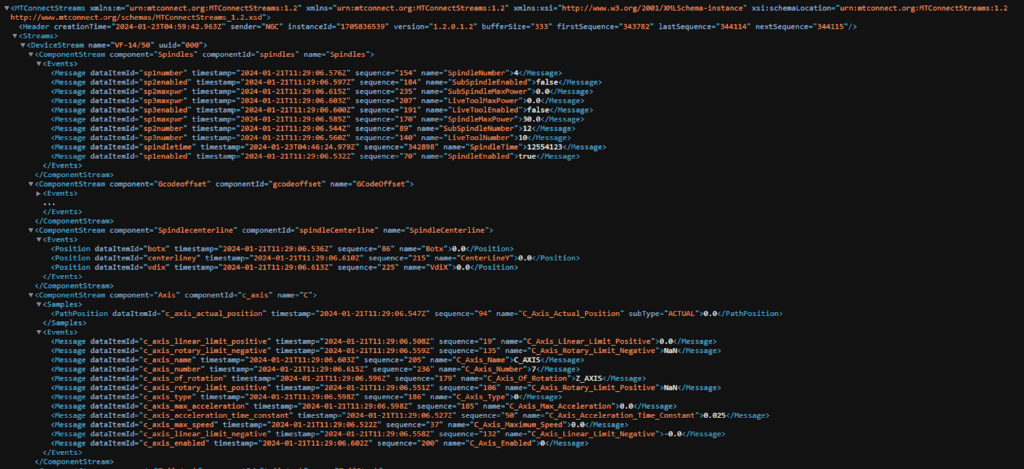

- A successful response will display XML data describing the machine status or metadata.

- Full address would be 172.21.16.31:8082/current for this example

Example Output (Current):

6. Troubleshooting Tips

Check Compatibility

- Confirm your software version meets the MTConnect requirement.

Firewall Port

- Verify port 8082 is open and allowed by your network’s firewall

Network Status

- Make sure the status is “UP” on the Haas controller

- Confirm you have set the Machine Data Collect option correctly

- Confirm you can ping the machine from your local subnet

7. Use Glassdome to Build Interactive Dashboards

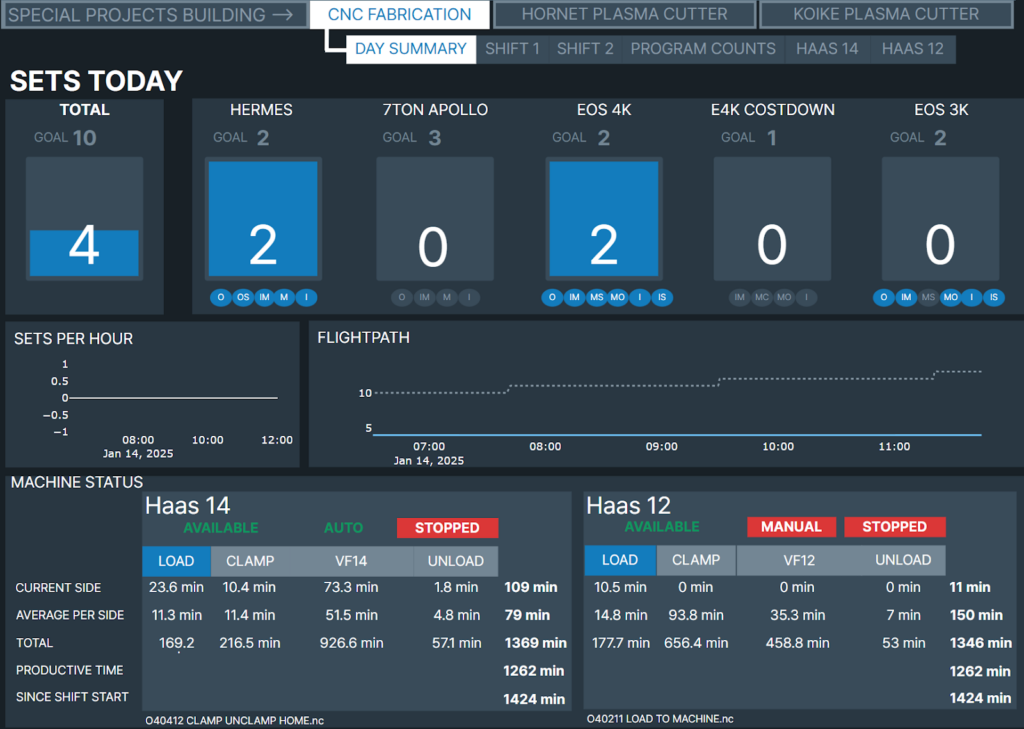

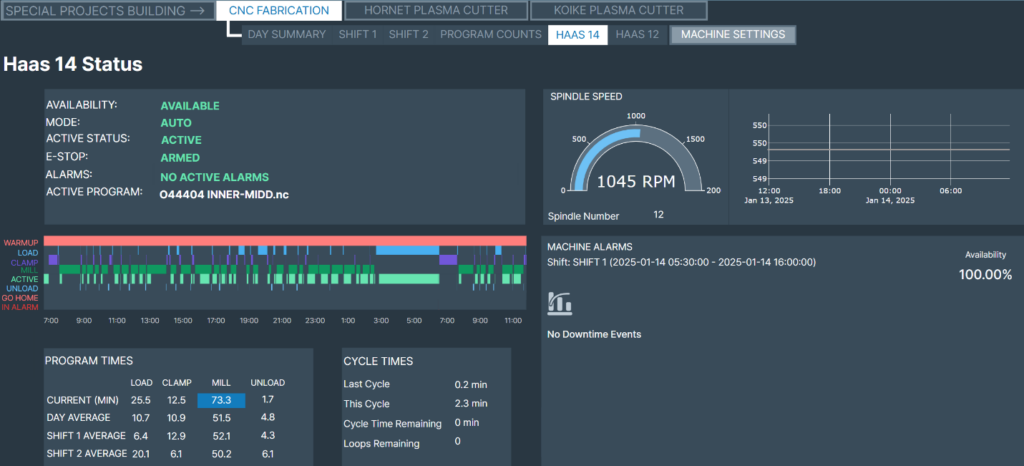

Once MTConnect is properly configured and responding on your Haas NGC controller, we can integrate your machine to Glassdome for real-time analysis.

Parse XML Data

- Glassdome automatically reads and interprets the MTConnectStreams XML.

- It extracts key performance indicators (KPIs) such as cycle time, machine state, and feed override.

Build Real-Time Dashboards

- Within Glassdome, create widgets or charts to visualize data points (e.g., spindle load or part counts).

- Customize layouts to highlight relevant metrics and display them on large monitors or individual workstations.

Historical Analysis

- While Glassdome primarily relies on the “Current” data stream, you can configure it to archive data for trend analysis.

- Compare past machine states, identify downtime patterns, and plan predictive maintenance.

Alerts & Notifications

- Glassdome’s alert system can send messages when certain thresholds (like spindle load) exceed safe limits.

- Receive notifications via email, text, or on-screen pop-ups, ensuring immediate attention to critical events.

Optimize Operations

- By correlating real-time metrics with other manufacturing data, you can optimize tool usage, improve scheduling, and reduce idle times.

- Data-driven insights from Glassdome help refine processes and support continuous improvement initiatives.

Dashboard examples from live Haas Machines outputting MTConnect:

Conclusion

Setting up MTConnect on your Haas NGC controller (e.g., VF-1450) opens the door to real-time monitoring and historical data review. If you encounter any challenges, reach out to your local Haas Factory Outlet or IT support.

By pairing this functionality with Glassdome, you can transform raw data into meaningful dashboards, alerts, and analytics—empowering you to make informed decisions and elevate productivity on the shop floor.

Ready to start finding and using the hidden data in your machines?

Talk with a Glassdome manufacturing expert today