More Data

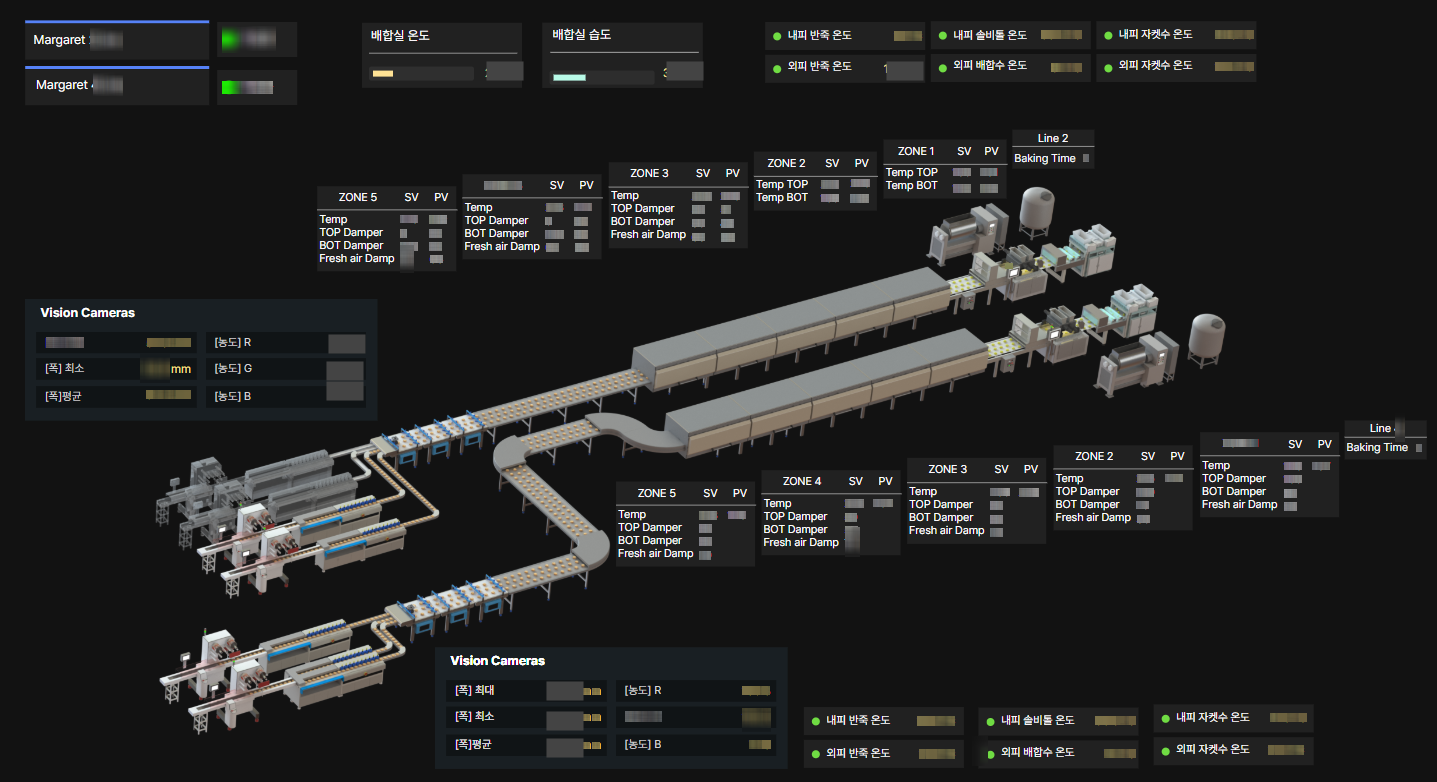

Glassdome connects to more machines than any competitor.

Get the live production data points you need to build a total view of your facilities.

And our hands-on experts help you every step of the way.

More Insight

Automated reporting helps you tell the story of every machine, shift, and facility.

Drag, drop, and design your perfect production view with our flexible canvas and hierarchy tools.

See live metrics like OEE, downtime, flight path, and more.

No Disruption

Simple IoT setup with native controller integration and LTE kickstart your monitoring.

Our solution works with the process you have, without requiring any changes in how you work.

White-glove service means you get up and running fast, and stay running when changes happen in your facility.

“Previously we were used to seeing very inflexible software vendors quote us millions of dollars for a fraction of features that Glassdome provides. We were really impressed with Glassdome’s field service for setting up new sensors and devices, and now are able to gather real time data for our major lines and use them in a browser. We’re very happy with Glassdome!”

– Project Manager, Lotte Wellfood

Why Implement Production Monitoring?

Production monitoring takes factories from clipboards and dry erase markers to total process visibility in a flash. It’s more flexible and granular than a legacy MES or ERP system, and much less of a burden to install and update.

Discover the seven ways production can change your production process.

TRANSPARENT PRICING

Glassdome’s Production Monitoring platform offers transparent pricing to fit your unique operations workflow.

Production Monitoring Software FAQs

Our production monitoring software seamlessly integrates with your existing systems, enhancing data collection and analysis without disrupting daily operations. We offer turnkey deployment, handling the technical aspects of integration without requiring advanced technical knowledge from your team.

Industries involving product manufacturing, like food and beverage, plastics, automotive, and aluminum, enjoy significant benefits from using greater visibility to implement continuous improvement and lean manufacturing practices to optimize their operations.

Small businesses can start with simple, scalable continuous improvement practices, focusing on areas with the quickest payback in terms of efficiency and cost savings. After observing your current processes, we recommend the most impactful improvements as part of our continuous improvement consulting services.

Production monitoring and continuous improvement initiatives reduce waste and enhance operational efficiency, directly contributing to lower carbon emissions and better resource management.

Glassdome provides comprehensive support, from initial assessment and strategy development to data integration, ongoing management, and continuous optimization of your processes and operations.

START GETTING THE MOST OUT OF YOUR MACHINES

Embrace continuous improvement with Glassdome and turn operational challenges into opportunities for growth and sustainability.