How can digital transformation help fix America’s aging manufacturing workforce?

By Glassdome

Digital transformation is helping American manufacturing sector navigate an aging manufacturing workforce and other sources of volitility. New regulations are shifting markets and processes. Supply chains are still significantly disrupted due to the coronavirus pandemic. And for many manufacturers the most critical issue is the imbalance between workforce supply and demand.

Too many openings, not enough workers

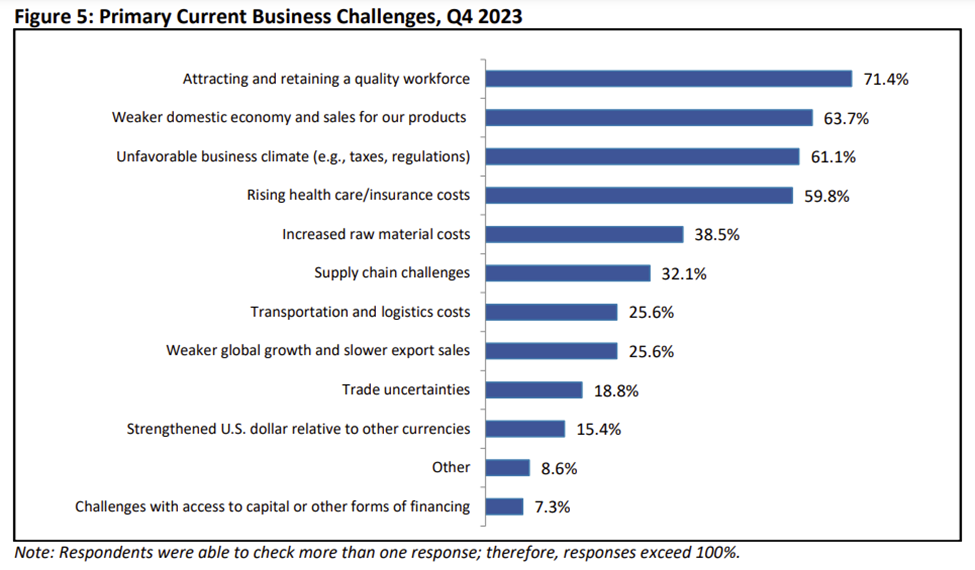

This concern is underscored by the findings of the National Association of Manufacturers’ 2023 Q4 outlook survey for the U.S. manufacturing industry. The survey reveals that the primary concern for manufacturing companies is recruitment and retention of qualified personnel. Companies feel a pressing need for new approaches to workforce management.

The task of sourcing workers for the manufacturing sector is becoming more and more challenging. By 2030, it’s anticipated that 4 million new jobs will emerge in manufacturing, yet an estimated 2.1 million of these positions are likely to remain unfilled. The inability to secure the necessary workers could end up incurring costs of close to $1 trillion in 2030 alone.

Is the aging workforce hitting manufacturing particularly hard?

A key reason behind this declining workforce is the aging demographic of the entire U.S. population. The baby boomer generation is nearing retirement, creating a nationwide hiring cliff. The labor market across the country is getting older.

The aging workforce issue is particularly acute in the manufacturing industry. Over 51% of workers are 45 and above and those over 55 constitute more than 25% of the workforce. It’s a trend that extends beyond a mere demographic shift in the overall population. Younger workers aren’t choosing manufacturing, despite competitive pay and strong benefits.

The challenge is compounded by the fact that it’s not just a decline in numbers, but a loss of skilled technicians. The retirement of these experienced workers means the departure of their accumulated know-how, posing a significant hurdle in maintaining enterprise-wide technical expertise. To mitigate this, many companies are encouraging imminent retirees to delay their retirement or are rehiring engineers who have already retired.

However, retaining these seasoned workers is not straightforward. Many are seeking a change from the traditional work environment. Older workers, for instance, are increasingly interested in reduced or more flexible working hours. Additionally, ensuring the safety of older workers can mean modifications to factory equipment or alterations in site layouts.

Even training those young workers that the industry is able to hire isn’t straightforward. Transferring the knowledge of retiring engineers to the new generation requires careful planning and execution. This transition, if not managed efficiently, could lead to reduced productivity or a loss of dynamism within the organization, further emphasizing the complexities of managing an aging workforce in the manufacturing sector.

How are American manufacturers adapting to the aging workforce?

If industry can’t find workers to fill roles, digital transformation needs to pick up the slack. Technology has come to the forefront.

Many companies have already integrated Information and Communication Technology (ICT) to enhance overall productivity and manufacturing efficiency. But companies are going beyond the basics. New innovations include using digital tools for human resource management, skill transfer, recruitment, and the formulation of worker safety policies.

Digital technologies like the Glassdome Production Monitoring platform can aid in tackling the challenges posed by an aging workforce in multiple ways:

Increased Productivity

Many areas of the production process remain undigitized. Whiteboards and clipboards rule. By digitizing these aspects, production can be managed more efficiently, even with a smaller workforce. (Hey, we help do that! Check out our platform).

Knowledge Transfer

The expertise of skilled technicians is more effectively preserved through digital means rather than on easy-to-lose and easy-to-tear paper. Digitizing training materials and creating comprehensive digital records of procedures and insights ensures the continuity and preservation of technical knowledge. This is invaluable for training new employees and maintaining work quality as older technicians retire.

Time and Location Flexibility

Digital transformation enables workers to monitor and manage processes remotely, so they can work from anywhere, whenever they’re needed. This is particularly beneficial for older workers or those returning from retirement who are looking for reduced or more flexible work schedules. With processes overseen from outside the factory, managers can ensure operational continuity and adaptability in human resource management.

Enhanced Worker Safety

Worker safety is crucial not only for regulatory compliance but also for employee retention (and general morals and ethics). Replacing manual processes with automated systems or machinery can reduce safety risks. Technology for preventive measures and education is getting more and more effective. Digitizing processes allows for data collection and analysis, enabling preliminary risk assessments and process improvements.

Additionally, using AI and IoT technologies for real-time monitoring and risk prediction, and employing virtual or augmented reality for safety training, significantly elevates workplace safety standards. This proactive use of IT technology ensures worker safety and aids in long-term employee recruitment and retention.

We can’t make your workforce younger. But we can help you move from whiteboards to iPads

And get all of your manufacturing data and processes out of technicians’ brains and into one secure place. Plus, we’ll help make your manufacturing more efficient and dramatically cut downtime. Take a look!