Lotte Infracell: A Data-Driven System for Carbon Regulation Compliance

OVERVIEW

Lotte Infracell is a specialized battery foil manufacturer with annual revenue of approximately $100 million. One of its flagship products is aluminum foil used in secondary batteries.

To comply with the increasingly stringent Carbon Border Adjustment Mechanism (CBAM) and battery regulations in Europe, Lotte Infracell adopted Glassdome’s product carbon footprint (PCF) calculation system.

PAIN POINTS

As European environmental regulations became more stringent, requiring detailed product carbon footprint (PCF) calculations, Lotte Infracell faced difficulties due to the complexity of the regulations and their multiple requirements.

Lotte Infracell aimed to calculate product carbon footprints accurately and efficiently in order to effectively comply with various regulations.

In addition, the company sought to leverage Glassdome’s dashboard to analyze high-impact emission factors and pursue ongoing carbon footprint reduction strategies.

KEY CHALLENGES

1. Difficulty in Data Collection

: Difficulty in consolidating data managed across multiple departments, leading to time-consuming processes.

2. Responding to Varying Regulatory Requirements

: Need to meet different calculation standards required by battery OEMs and the EU CBAM regulation.

3. Difficulty Identifying Reduction Opportunities

: Although data was available, it was difficult to analyze the impact of each factor, making it hard to develop reduction strategies.

4. Challenges in Securing Carbon Footprint Data for Raw Materials

: Difficulty obtaining accurate carbon intensity data for raw materials with high carbon impact.

ROOT CAUSE ANALYSIS

- Lack of a system to automate and monitor carbon footprint calculations

2. Inefficiencies caused by fragmented data across departments

3. Low accuracy due to insufficient granularity in data

4. Lack of in-house expertise

SOLUTIONS

Lotte Infracell adopted Glassdome’s PCF solution with the goal of integrating fragmented data into a single system and establishing a sustainable framework for carbon footprint management.

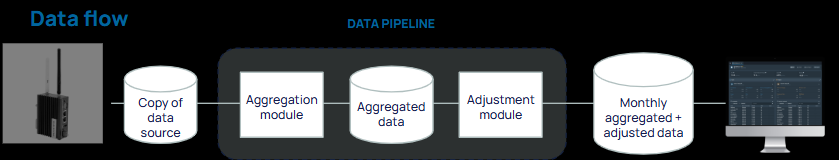

Through the project, the company developed a system to collect various data sources and transform them into a format suitable for carbon footprint calculation.

Based on this, Lotte Infracell established a framework to analyze the results and support the development of future carbon reduction targets.

The following outlines the implementation conducted for two products at selected Lotte Infracell manufacturing sites in Korea.

ON-SITE CASE STUDY

- Key Data Collection:

- Sensors were installed on each piece of equipment to collect and monitor real-time and cumulative usage data for electricity and LNG.

2. Collecting production-related data dispersed across legacy systems

- Establishment of Equipment Energy Monitoring System

: Real-time energy usage data is collected and monitored based on the installed sensors.

- PCF Data Pipeline Development

: Automated a Gate-to-Gate data template by process and product, based on data collected in accordance with ISO 14067 standards.

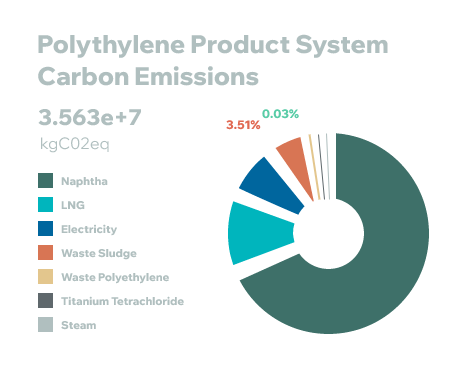

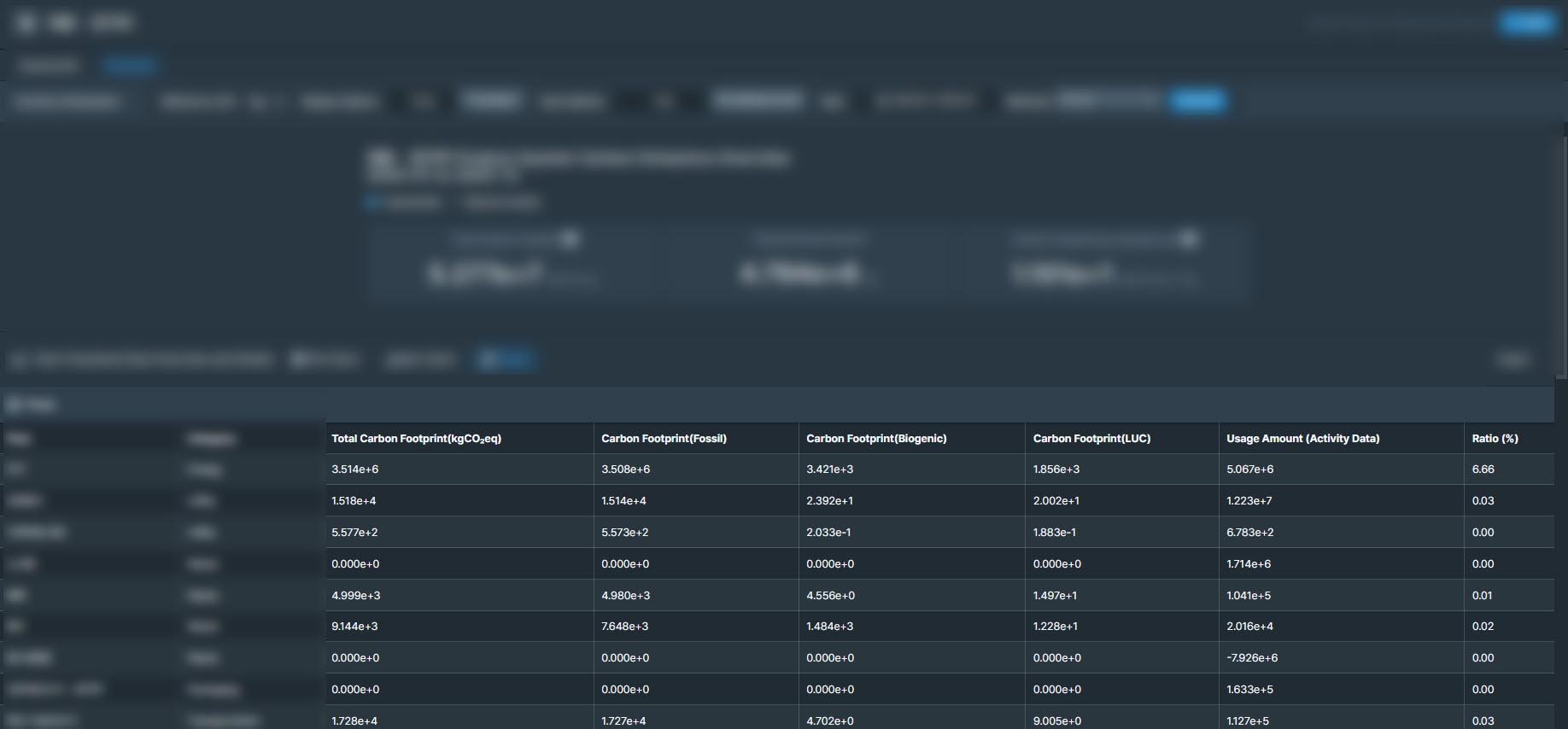

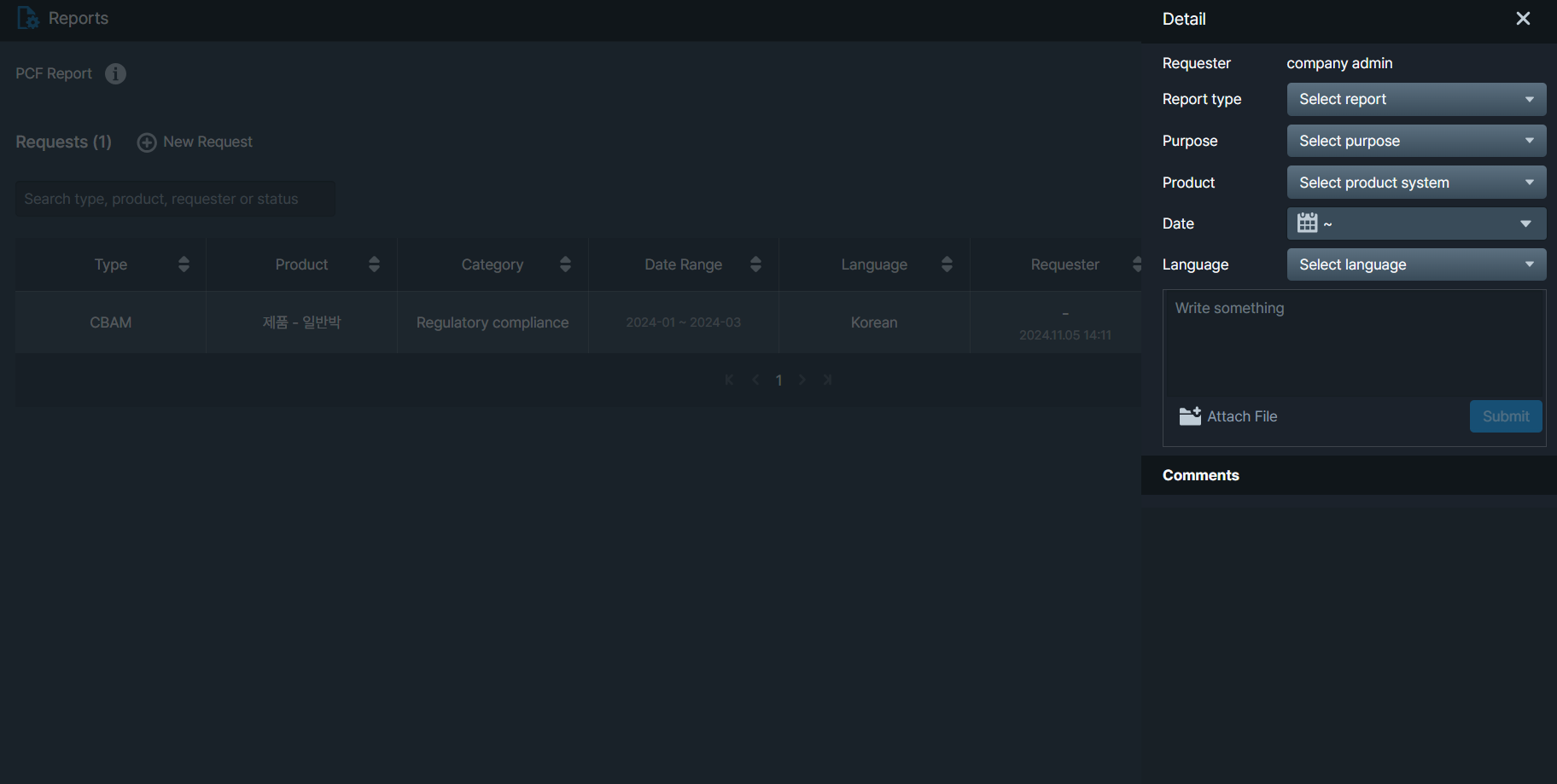

- Product Carbon Footprint and CBAM Calculation

: Calculated final results based on the structured pipeline data, in accordance with ISO 14067 or CBAM regulatory requirements.

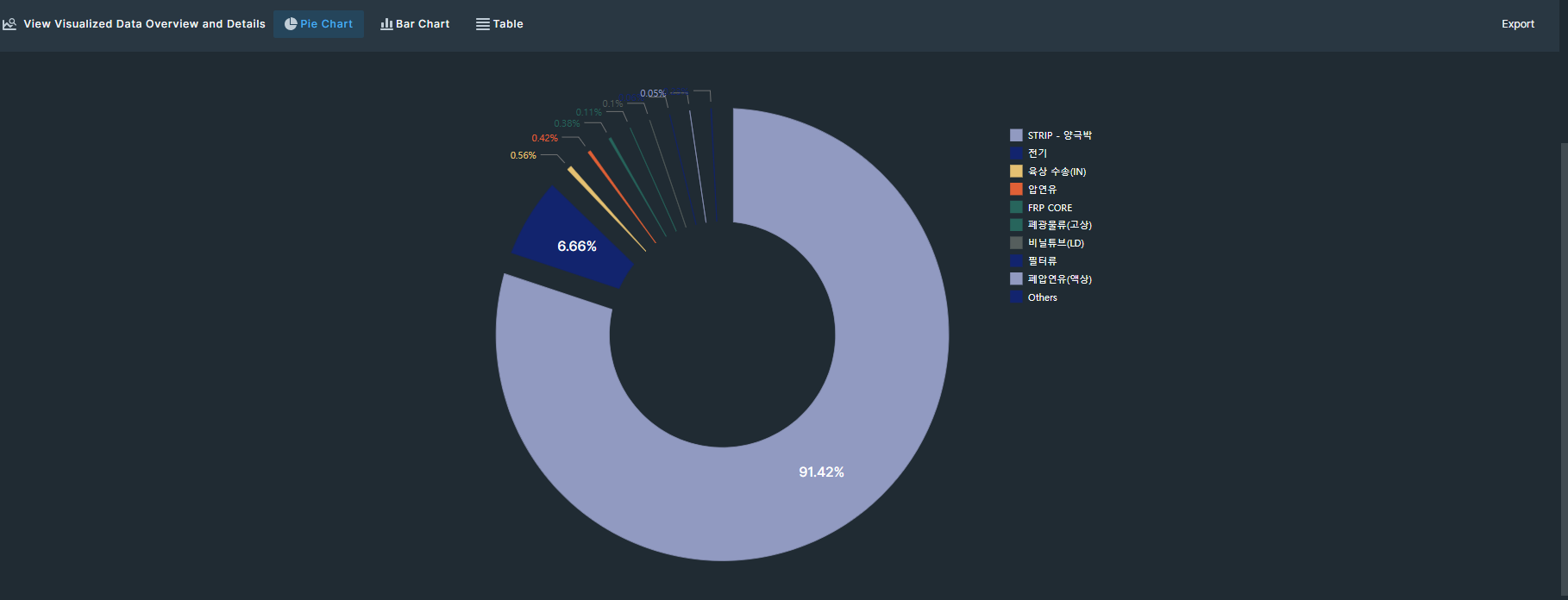

- Impact Analysis by Category

: Analyzed and visualized the impact of key data points based on the results to identify priority areas for carbon footprint reduction.

- Verification Report Support

: Prepared documentation for third-party verification.

RESULTS

Through this project, Lotte Infracell achieved the following tangible outcomes:

- Improved operational efficiency through real-time energy monitoring

➝ Operators can now monitor equipment conditions centrally via a real-time dashboard instead of checking on-site manually.

- Faster response to regulatory requirements

➝ The collected data enables faster responses to CBAM and battery regulations, reducing overall work time.

- More accurate carbon footprint calculation

➝ Aligned with the regulatory trend toward primary data, actual operational data was used to enhance calculation accuracy.

- Reliable supply chain data acquisition

➝ Reliable carbon footprint data can now be obtained based on verified supply chain inputs.

NEXT STEPS

Following the successful completion of the project, Glassdome and Lotte Infracell are now working on advancing the CBAM-related functionalities.

With these enhancements, the system is expected to respond more flexibly and systematically to the growing complexity of CBAM regulations.

CONCLUSION

Lotte Infracell’s collaboration with Glassdome resulted in a PCF and CBAM management system that achieved key outcomes: real-time data collection, data analysis, and sustainable regulatory compliance.

With the system now fully implemented, Lotte Infracell plans to continue responding systematically to the tightening regulatory landscape.

To proactively respond to the EU’s carbon-related regulations, we established a Carbon Emissions Calculation Platform in 2024.

Through this platform, we are now able to secure accurate and reliable emissions data based on real-time monitoring by process.

The ability to manage data in real time in alignment with various EU regulations has been highly beneficial.

— Lotte Infracell

POWER UP YOUR

MANUFACTURING EFFICIENCY AND CARBON REPORTING