See how a agricultural machine giant gained a complete view of their factory

OVERVIEW

Daedong Corporation (known as Kioti in North America) is one of the largest agricultural machinery manufacturers in the world, with a product range covering tractors, combine harvesters, ATVs, engines, and more. Founded in 1947, the company has a revenue of over $1 billion.

CHALLENGE

Daedong had an existing MES system, but it did not provide the company with the level of visibility it needed to monitor and improve its operations.

The goal was to create single-pane-of-glass visibility for plant managers, and give production line, facilities maintenance, and quality assurance workers the information they needed to do their jobs effectively with a minimum of distractions.

Although the Daedong team had initial concerns about the system operation and security of a cloud CI tool, they decided to adopt the Glassdome solution.

SOLUTION

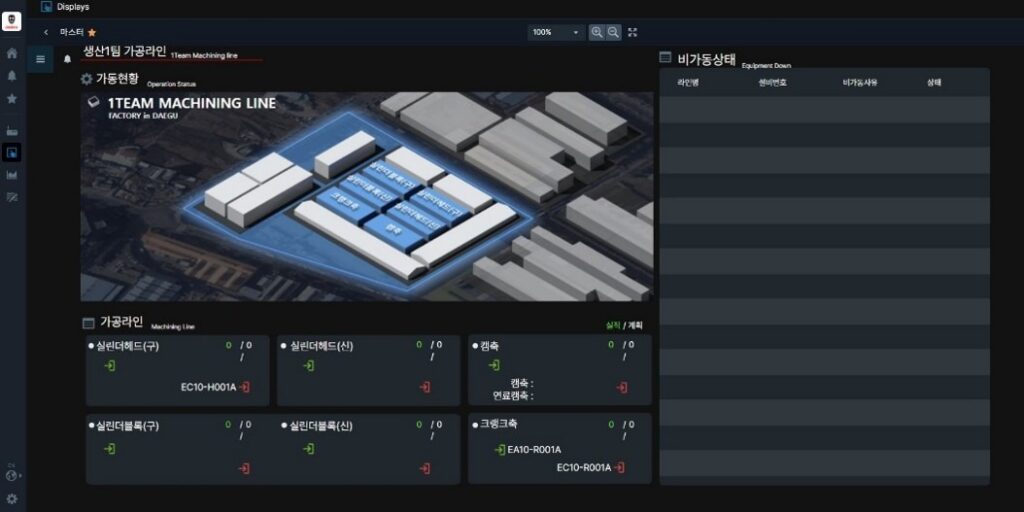

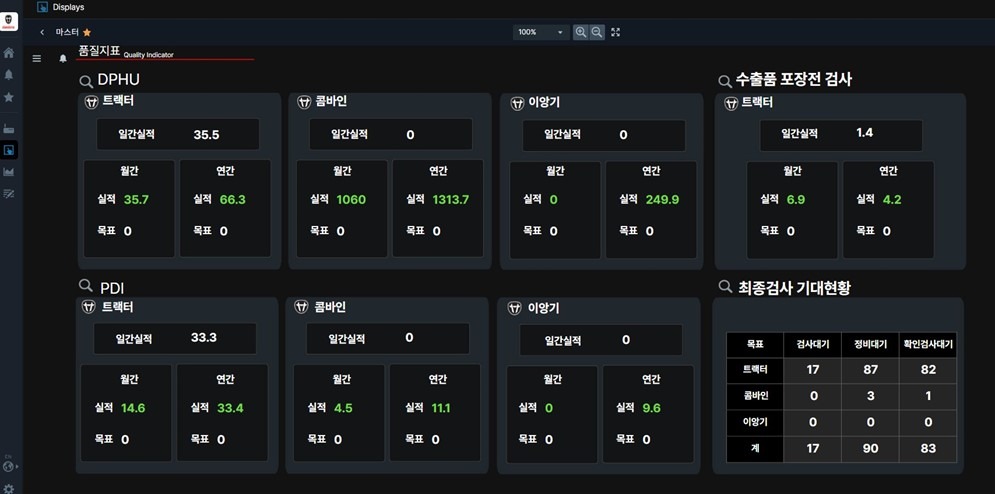

Glassdome implemented a system that works with the existing MES to enable real-time production process monitoring and created a plant overview dashboard and four team-specific dashboards that show on monitors across the facility.

We started by installing a Glassdome gateway in the DMZ of the server network to collect data directly from the MES server. Our gateway gave the client scalability and stability, allowing data collection from all equipment at one point, and wireless integration.

Our secure deployment responded to the client’s security concerns. The gateway has hardware information security including TrustZone architecture technology and a secure boot environment. Communication security involves TLS for secure data transmission and AES-128 encryption.

A dedicated LTE network provides enhanced security, encryption (NAS, AES), and integrity protection, restricting un-authenticated devices and blocking external internet access. And it does it at a lower setup and maintenance cost than WiFi or wired networks.

We used that data to build customized dashboards. Every room in the factory has access to the plant overview dashboard, and two unique production teams, facility maintenance, and quality assurance each have their own custom dashboard.

Our dashboards include metrics like personnel status, production performance (including running/non-running notification), line operation and quality index performance. They can be drilled down by line, by product, and by machine.

Additional tools like a 360 indicator, dynamic visuals, and conditional visibility features were built out after the initial deployment as part of our ongoing customer support.

Main Screen:

Main Line 1:

Quality Assurance:

RESULTS

The completed project has delivered unprecedented visibility to Daedong’s employees, from the executive team down to individual line workers.

By taking the leap on a cloud solution, the company has benefited from lower hardware costs, flexible global system scalability, and consistent speed, stability, and maintenance.

We are continuing to roll out refinements to the monitoring system, and a project to collect data directly from the factory equipment, supplementing the MES system, is under ongoing consideration.

POWER UP YOUR

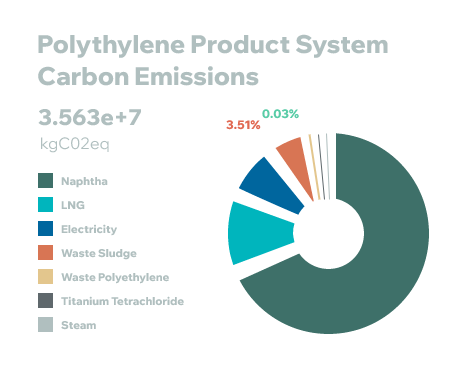

MANUFACTURING EFFICIENCY AND CARBON REPORTING