“Previously we were used to seeing very inflexible software vendors quote us millions of dollars for a fraction of features that Glassdome provides. We were really impressed with Glassdome’s field service for setting up new sensors and devices, and now are able to gather real time data for our major lines and use them in a browser. We’re very happy with Glassdome!”

– Project Manager, Lotte Wellfood

Guided Process,

Measurable Results

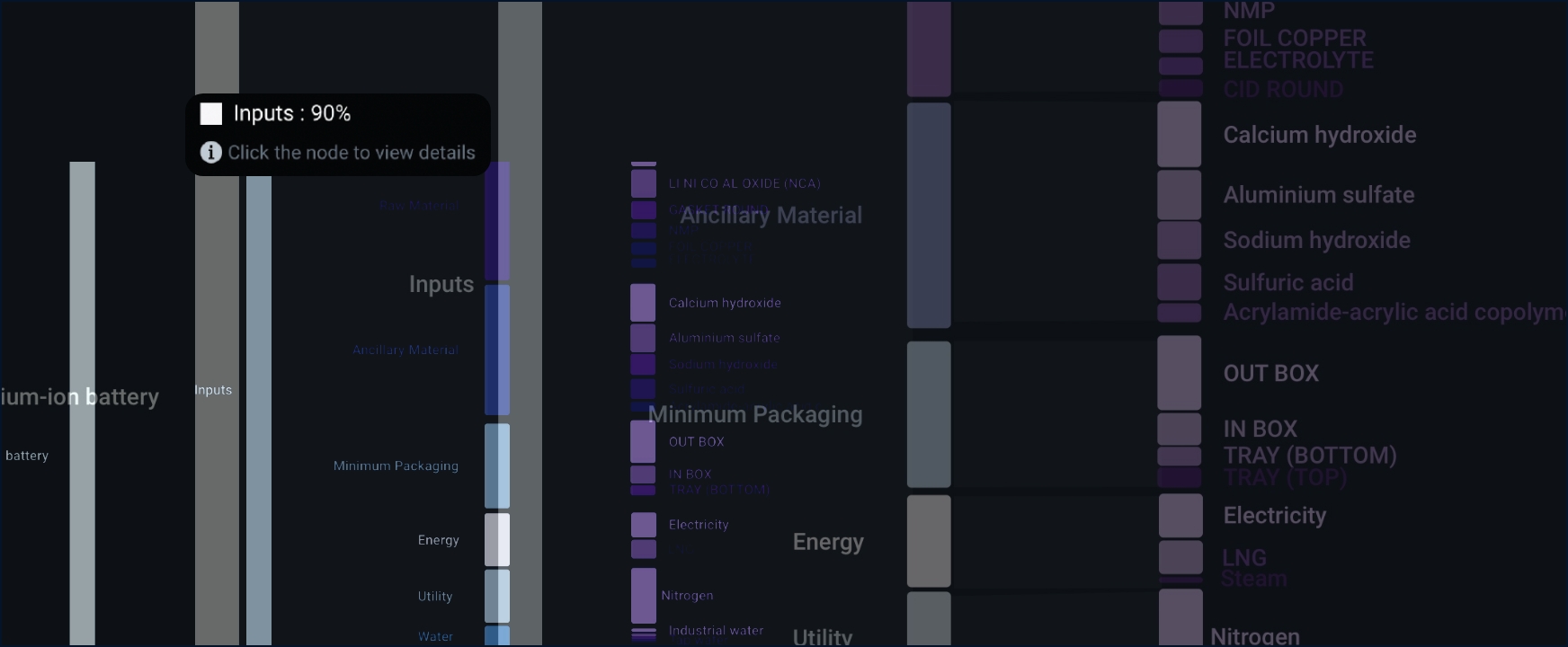

Our process starts at the heart of your operations. We harness data directly from your facilities and their equipment, ensuring nothing is overlooked. Here’s how we turn complex data streams into actionable insights:

GUIDED PROCESS.

POWERFUL RESULTS.

Our process starts at the heart of your operations. We harness data directly from your facilities and their equipment, ensuring nothing is overlooked. Here’s how we turn complex data streams into actionable insights:

Understand Your Data, Drive Your Success.

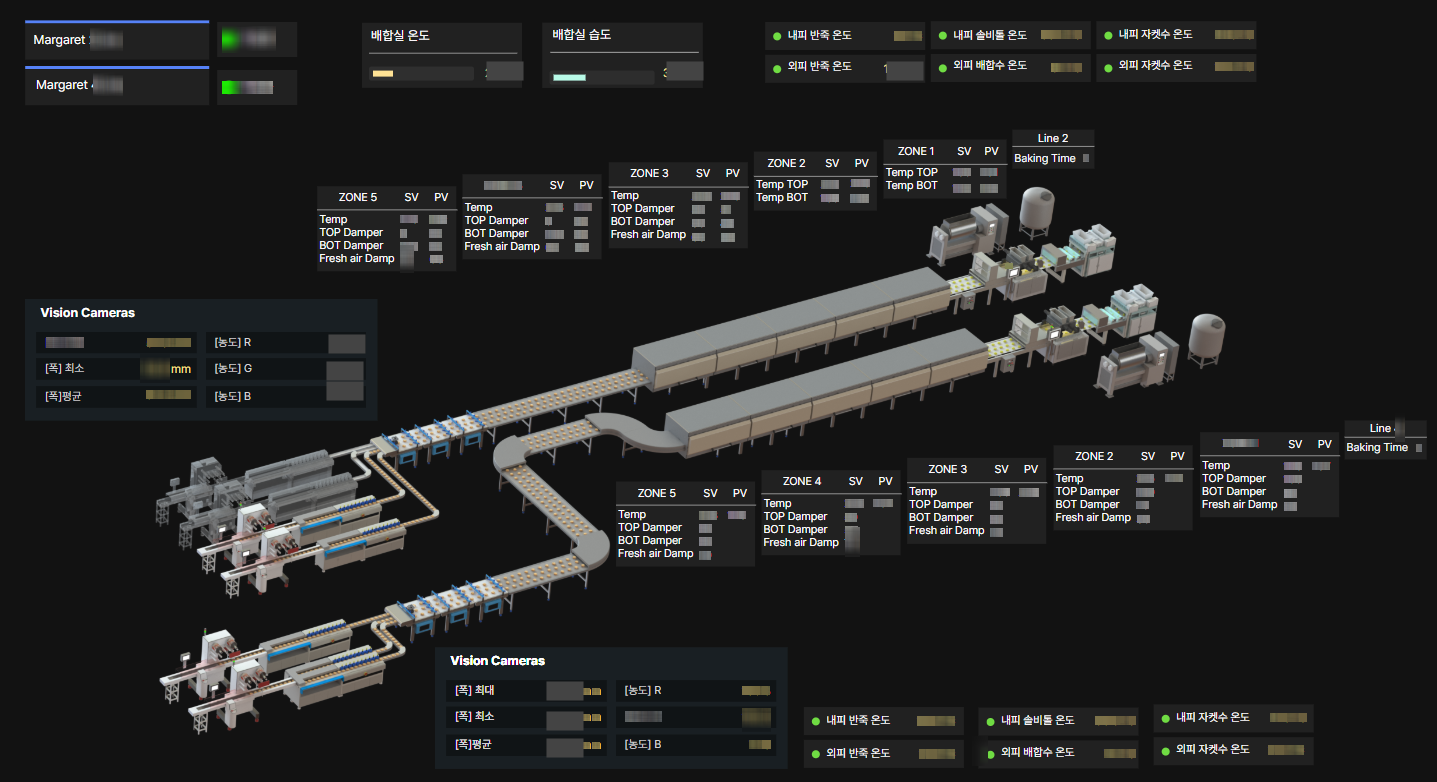

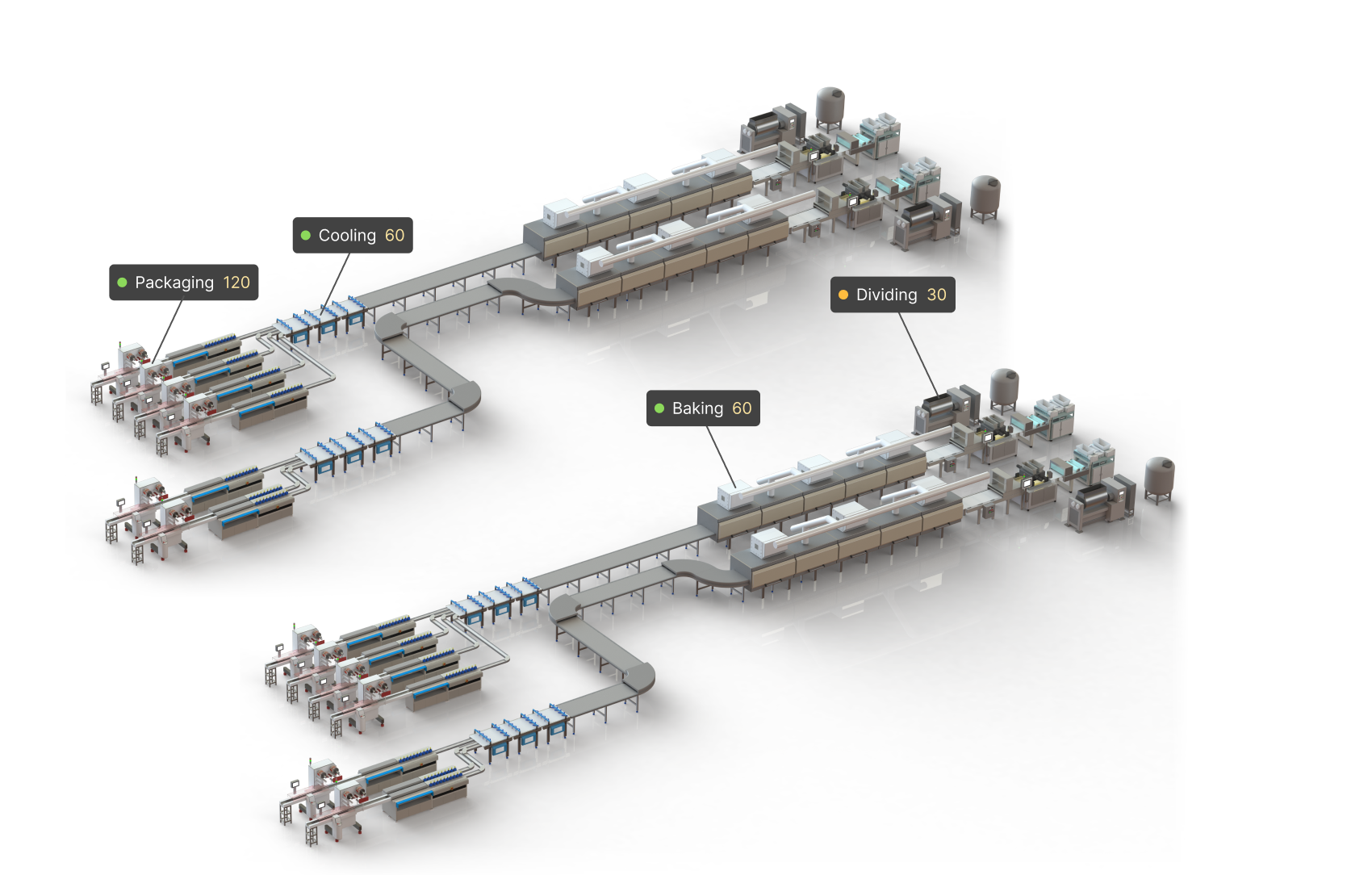

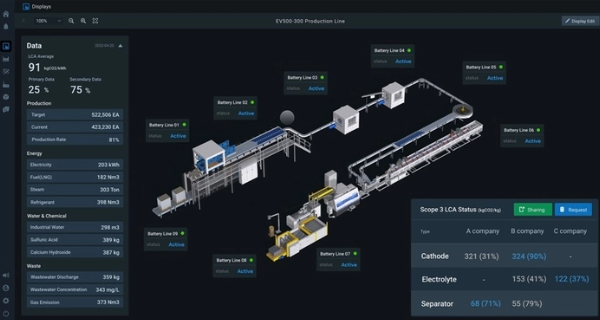

Boost efficiency with real-time data

Our production monitoring software shows you exactly where and how to optimize. Whether it’s cutting downtime, speeding up production, or improving product quality, Glassdome helps you pinpoint and fix inefficiencies fast.

Stay ahead of sustainability regulations

With our product carbon footprint (PCF) tools, you’ll meet compliance requirements while understanding the environmental impact of every product. Reduce your carbon emissions and ensure future sustainability success.

Product Carbon Footprint (PCF), also known as CFP, is a measure of the total greenhouse gas emissions produced by a product throughout its lifecycle — from creation to disposal. This comprehensive lifecycle measurement is critical for assessing environmental impact.

We Handle the Integration, You Enjoy the Results

We simplify the process of integrating machine data and ERP systems, giving you full operational visibility without headaches.

“Glassdome’s software helped us solve a problem that would have resulted in hundreds of thousands of defects. We were able to view this problem remotely in Vietnam and act in real time in Korea, which was mind blowing!”

– Project Manager, Orion

POWER UP YOUR

MANUFACTURING EFFICIENCY AND CARBON REPORTING

Get the Latest

Glassdome News & Info

Glassdome’s VP, Jinki Ham, Announces the Launch of the World’s First Real Data-Based Carbon Footprint Solution

Glassdome Product Environmental Footprint solution ensures the secure transfer of only carbon footprint calculations to the export company, preventing the leakage of sensitive data between the main contractor and partner company.

Read