기존 설비를 교체하지 않고 IoT에 연결하는 방법

By Jordan Cota

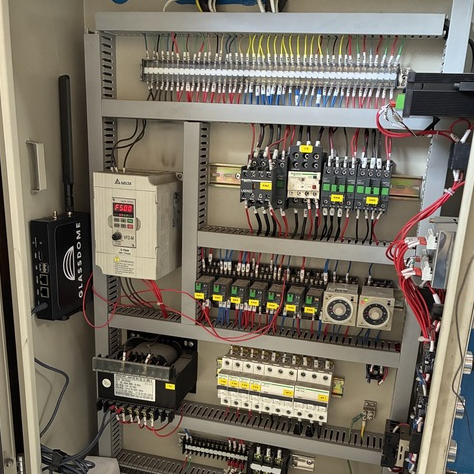

글래스돔의 솔루션을 통하면, ‘최신식 장비’가 아니더라도 설비를 연결 및 모니터링이 가능합니다. 동서독 분단 이전에 제작된 오래된 설비를 흔히 ‘Big Bertha’라고 부르는데, 글래스돔은 이러한 레거시 장비와도 연동할 수 있는 다양한 방법을 보유하고 있습니다. 아직 완벽하게 잘 작동하는 전단기나 밴드쏘(띠톱)를 단지 ‘낙수 효과 이론’을 기억할 만큼 오래되었다는 이유만으로 교체할 필요가 있을까요? 글래스돔은 장비의 연식이나 운영 방식에 관계없이, 거의 모든 설비를 자사 플랫폼에 연결할 수 있습니다. 이를 통해 실시간 상태, 가동·비가동 시간, 생산 수량, 알람 이벤트 등 다양한 데이터 모니터링할 수 있었습니다. 저희는 전류 트랜스듀서(CT), 포토센서(photo-eye), 습식 접점(wet contact), 건식 접점(dry contact) 등을 활용하여 기존의 오래된 설비를 21세기형 스마트 설비로 전환합니다. 만약 여러분의 장비가 Haas CNC처럼 비교적 최신형이라면, 더욱 다양한 데이터와 활용 옵션을 확보할 수 있습니다. 이번 설명에서는 글래스돔이 노후 설비에 Industry 4.0을 적용하는 여러 가지 방법들 중 일부를 소개합니다. 또한, 실제 현장에서 어떻게 적용되는지를 보여주는 실사례를 통해 그 과정을 설명하고자 합니다.

글래스돔은 공장 현장의 설비 데이터를 자사 플랫폼으로 전달하기 위해 다양한 유형의 IoT 디바이스, 즉 ‘게이트웨이(Gateway)’를 활용하고 있습니다. 특히 노후 설비의 경우, 하드와이어드(hard-wired) 또는 하드웨어 기반 연동이 가능한 게이트웨이를 주로 사용하며, 자체 개발한 글래스돔 전용 소프트웨어가 내장된 EDATEC CM4 Industrial을 적용하고 있습니다. 해당 장비는 현장 환경에 최적화된 산업용 장치로, 셀룰러(Cellular), 이더넷(Ethernet), 와이파이(Wi-Fi) 연결 방식을 자유롭게 전환하여 언제나 안정적으로 플랫폼과의 연결을 유지할 수 있습니다. 또한 디지털 입력 신호와 아날로그 입력 신호를 모두 지원하여, 설비의 현재 상태를 파악할 수 있는 것이 큰 장점입니다. 이와 더불어 Allen-Bradley의 EIP, Modbus, MTConnect, OPC-UA, Siemens S7, TCP 등 최신 산업 통신 프로토콜도 폭넓게 지원합니다. 글래스돔은 이러한 기술 기반을 통해 안정적인 지원을 제공합니다.

그럼 본격적으로 시작해보겠습니다.

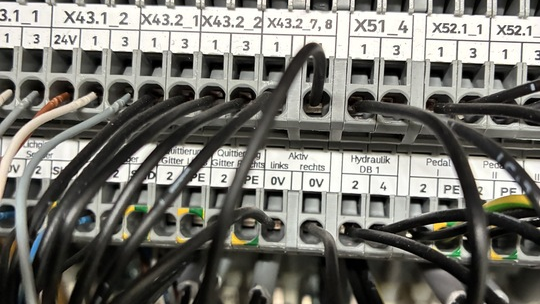

Thalmann Metal Folder

이 장비는 비교적 최신 설계와 제어 시스템을 갖추고 있으며, EtherCAT 기반의 Beckhoff 시스템을 사용하고 있었습니다. 일반적으로는, Beckhoff 컴퓨터에 직접 접근하여 ‘Is-Running(가동 여부)’, ‘Part Complete(작업 완료)’, ‘Fault(장애)’ 등의 변수를 추출하는 방식을 활용합니다. 하지만 이 방식은 장비의 프로그램에 대한 직접적인 접근 권한이 필요하며, 해당 장비의 OEM에서는 이를 허용하지 않았습니다. 이에 저희는 장비의 도면을 확인한 후, I/O 보드에 있는 ‘Active Light’ 신호를 활용할 수 있다고 판단했습니다. 이 신호는 기본적인 24V DC 신호로, 해당 표시등에 24V 전압이 인가되거나 전류가 흐를 경우 장비가 가동 중이라는 것을 의미합니다. 이를 통해 장비의 가동 상태를 확인할 수 있을 뿐만 아니라, 장비가 완료한 사이클 수(작업 횟수)도 함께 집계할 수 있습니다.

Hydmech – 밴드쏘(띠톱)

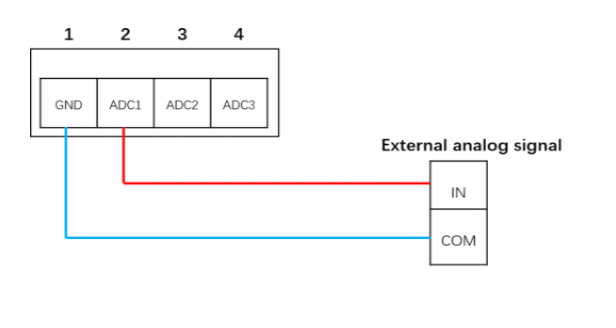

고객사는 여러 대의 밴드쏘(띠톱) 설비의 가동률을 모니터링하고, 다운 타임 발생 시 알림을 받기를 원했습니다. 해당 장비들은 컨트롤러나 제어 시스템, 즉 ‘두뇌’ 역할을 하는 장치가 없는 저사양(로우테크) 설비였습니다. 따라서, 소프트웨어 연동이 아닌, 하드와이어드(hard-wired) 방식의 솔루션이 필요했습니다. 이에 저희는 전류 트랜스듀서(CT)를 활용하여 밴드쏘(띠톱) 모터로 유입되는 전력을 측정하는 방식으로 장비 상태를 모니터링하기로 결정했습니다. 모터에 전력이 공급되고 있다면, 해당 장비는 가동 중인 상태로 판단합니다.

Metal Bender (금속 밴더)

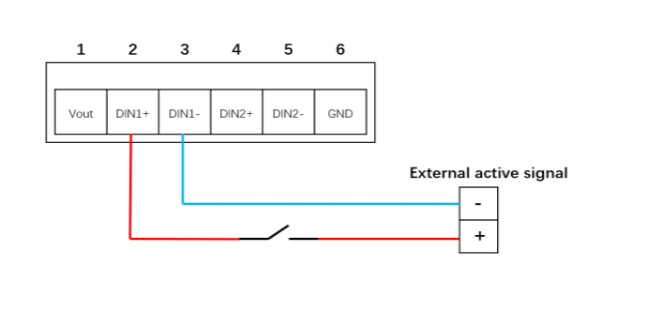

고객사는 해당 벤더(bender) 설비의 가동 시간, 비가동 시간, 그리고 생산 수량을 모니터링하고자 했습니다. 앞서 소개한 다른 장비들과 마찬가지로, 이 장비 또한 내부 컴퓨터 시스템에 직접 접근할 수 있는 방법이 없었습니다. 이에 장비의 전기 도면과 회로도를 검토한 결과, 장비가 사이클을 시작하거나 제품 생산을 개시할 때 KA4 릴레이가 닫히면서 전압이 흐른다는 점을 확인했습니다. KA4는 리미트 스위치(limit switch)에 의해 제어되며, 장비가 하나의 사이클을 시작하면 본격적인 가공에 들어가기 전에 먼저 리미트 스위치를 접촉하여 전원이 인가됩니다. 시스템을 구동하는 모터를 활용하는 방식이 더 간단할 수도 있었지만, 해당 장비는 유압 기반 시스템으로 구성되어 있어 모터가 항상 작동 중입니다. 즉, 모터가 작동하고 있다고 해서 실제 제품이 생산되고 있다는 의미는 아닙니다. 따라서 Vout을 릴레이 입력 측에 연결하고, 릴레이 출력 측을 DIN1+에 연결함으로써 리미트 스위치의 활성화 여부를 정확하게 감지할 수 있도록 구성했습니다. 이를 통해 사이클 시작 시점을 파악할 수 있으며, 전체 사이클 수(총 생산 횟수)도 함께 집계할 수 있습니다.

Metal Shear Machine (금속 전단기)

이 금속 전단기는 이름 그대로 금속을 절단하는데 사용되는 장비입니다. 하지만 장비의 실제 가동 빈도와 일일 사이클 수를 정확하게 파악할 수 없는 문제가 있었습니다. 이 문제에 대한 가장 간단한 해결 방법은 장비에 확산형 포토센서(diffused photo-eye)를 부착하는 것 이었습니다. 분석 결과, 금속을 절단할 때 전단기의 샤프트가 포토센서가 감지할 수 있는 범위 내로 내려온다는 점을 확인했습니다. 이에 포토 센서의 상태가 5분 이내에 ON/OFF로 변할 경우, 해당 장비가 가동중인 상태로 판단하도록 설정했습니다.

최종 정리

여러분의 설비가 Industry 4.0에 참여하기 위해 최신 장비일 필요는 없습니다.

인터넷 이전에 제작된 장비든, 베를린 장벽 붕괴 이전의 설비든, 디스코 시대의 기계라 할지라도, 움직이고 사이클을 돌며 전력을 소비한다면 글래스돔이 모두 연결하고 모니터링합니다.

이제 레거시 설비를 디지털 환경으로 전환할 준비가 되셨나요? 저희 팀에 연락 주시면 현장 진단을 통해 각 장비에 가장 적합한 연결 전략을 제안해드립니다. 멀쩡한 설비를 폐기할 필요가 없습니다.

Need to get your “Big Bertha” online?

어떤 환경에서도 적용 가능한 스마트 생산 모니터링 시스템을 도입해보세요.

![[기술 가이드] OT 네트워크에서 NAT 장치가 필요할 수 있는 이유 & Allen Bradley 1783-NATR 설정 방법](https://glassdome.com/wp-content/uploads/2025/03/bfa4aab8-3ebc-48cd-8ce1-5fd121b503b9.png)