Carbon Footprint Data Exchange Protocols & Frameworks Guide

By John Wright

Carbon Footprint data exchange is at the heart of decarbonization. Deriving your gate-to-gate product carbon footprint, even with your own real data, is just the first step in finding the true carbon impact of what you create.

Scope 3 emissions, created by activities upstream or downstream of a product’s manufacture, often make up the majority of its embedded carbon usage. But they’re hard to measure and can’t be solved in isolation. Companies need to build supply chain engagement and collaboration, even as companies up and down the value chain are understandably nervous about handing over detailed production data.

As the PACT Methodology writes, “It is important to emphasize that the goal to accelerate decarbonisation of value chains cannot be solved by individual actors in isolation. It requires an aligned, coordinated, and open approach, driven jointly by stakeholders across all industries and value chains, including SMEs. Radical collaboration is key.”

That’s where Product Carbon Footprint (PCF) data exchange protocols and frameworks come into play. They ensure accuracy by helping every member of the chain submit their data in a clear, standardized format. And more advanced protocols help members handle the technical aspects of submission and exchange by giving users a platform for inputting and accessing data.

Different regions and industries have their own PCF data exchange protocols and frameworks. In this insight, we’ll look at four major options: Catena-X, Ouranos, Together for Sustainability (TfS), and PACT.

Catena-X

Catena-X is an open data ecosystem developed in Germany for the automotive industry, designed to create data chains that will enhance the overall value chain. It is compliant with, and developed alongside, the broader Gaia-X federated European cloud platform.

Its goal is to become an interoperable collaboration that promotes innovation, increases efficiency, and enables easy compliance. A broader aim is for it to serve as a model across industries through their own Manufacturing-X initiatives.

Automotive value chains are long and complex. Catena-X acts as a standardized model for data exchange and collaboration. It brings every manufacturer, supplier, and technology partner together to track every part, material, and vehicle throughout its lifecycle. Its open, participatory approach relieves means it doesn’t rely on a single organization to track everything by itself.

Catena-X is built on a modular use-case architecture. Initial applications for Catena-X include product carbon footprint tracking, battery and product passports, supply chain track and trace, and data management. Through this initial work, it can encourage and ultimately enforce sustainable production practices and lower administrative and production costs.

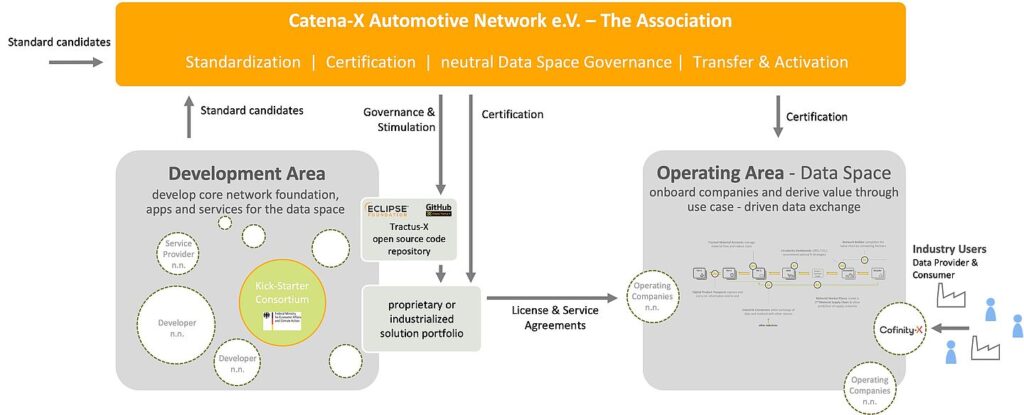

The initiative is split into three areas.

- The Catena-X Association governs the data space and handles standardization, certification, release management, and other day-to-day tasks.

- The Development Environment includes the Eclipse Tractus-X open source project and GitHub pages for Tractus-X and Catena-X.

- The Operating Environment ensures the operation of the data ecosystem. It’s run by Cofinity-X.

All three environments work together to build transparency and foster the creation, operation, and sharing of data chains in the automotive value chain.

Ouranos

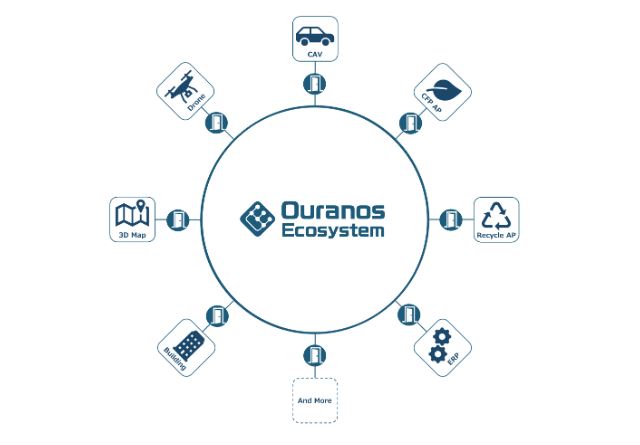

The Ouranos Ecosystem is an effort led by the Japanese Ministry of Economy, Trade, and Industry (METI) to bring together industry, academia, and government to ensure data interoperability and allow users to exchange, understand, and use data from many sources. Carbon footprint data exchange is a small piece of a huge undertaking.

The ultimate goal of Ouranos is to create a “data space,” where users can pull data from wide-ranging sources to realize the Japanese government’s Society 5.0 ambitions and address social challenges like labor shortages, natural and human disasters, and decarbonization. By applying rules, security, and governance to the vast array of data Japan already has access to, it hopes to position itself as a leader in a digital future.

Ouranos is not only built to solve internal issues in Japan. Collaboration with European efforts, including an MOU with the Catena-X Automotive Network, will accelerate Japanese companies’ ability to trace their products up and down their value chains through a “supply chain data linkage platform.”

Much like Catena-X, the automotive industry is driving the development of this data exchange platform. One of its initial use cases is the European Battery Regulation, which mandates a product passport including a verified product carbon footprint. Achieving those requirements demands a high level of data management across the battery value chain. In 2024, Fujitsu demonstrated its ability to convert and verify information between its Ouranos-compatible Uvance data space, and related data spaces in Europe.

Much like the European initiatives, Ouranos’ creators hope to strengthen and streamline the global supply chain. With data visibility, issues like carbon neutrality, economic security, waste reduction, and traceability can all be far more effectively addressed. And simple, standard data protocols allow small-to-medium sized enterprises (SMEs) and startups to participate without a crippling administrative burden.

Beyond batteries, METI sees the benefits of data connectivity expanding into aviation, finance, and healthcare, and accelerating a self-reliant circular economy by using data sharing to cut dependence on external raw materials.

Together for Sustainability (TfS)

While Catena-X and Ouranos are regionally-oriented efforts, Together for Sustainability (TfS) is industry-based.

TfS is a member-driven initiative dedicated to raising corporate social responsibility (CSR) standards in the chemical industry. According to Deloitte, Scope 3 emissions make up 75% of the carbon footprint of chemical products. TfS is a collaboration between chemical companies to help monitor, manage, share, and reduce those emissions.

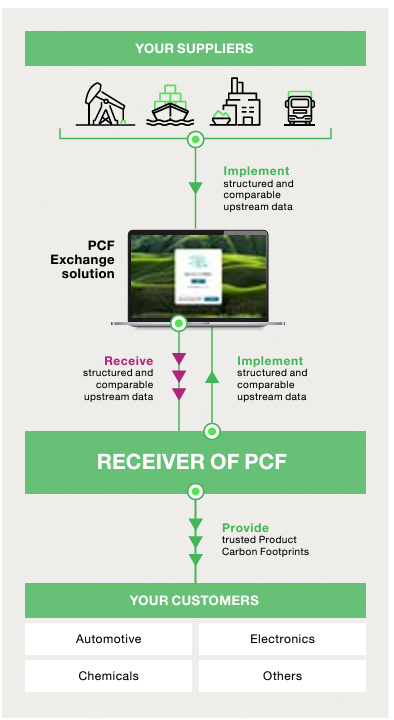

The TfS Scope 3 GHG emissions program is made up of two tools designed to get chemical companies the data they need to calculate their own PCFs: a PCF guideline framework for chemical companies and suppliers, and the TfS PCF Exchange solution.

The TfS PCF Guideline is designed to be a transparent, simple standard for calculating emissions in chemical supply chains. This open source framework provides step-by-step calculation instructions for suppliers and other relevant industries to calculate their PCFs. Armed with standardized data, chemical companies can set tangible emissions reduction targets and drive decarbonization. PCF calculation is still a major administrative lift (at least, if you don’t have a platform like Glassdome), but this reduces much of the confusion and inertia that comes with it.

The TfS PCF Exchange is the technical platform that enables companies to share and use the calculated PCF data. Powered by Siemens SiGREEN (a Glassdome partner), it provides a transparent, secure, and scalable environment to safely exchange PCFs, without also exchanging potentially sensitive information that goes into those PCFs.

PACT (Partnership for Carbon Transparency)

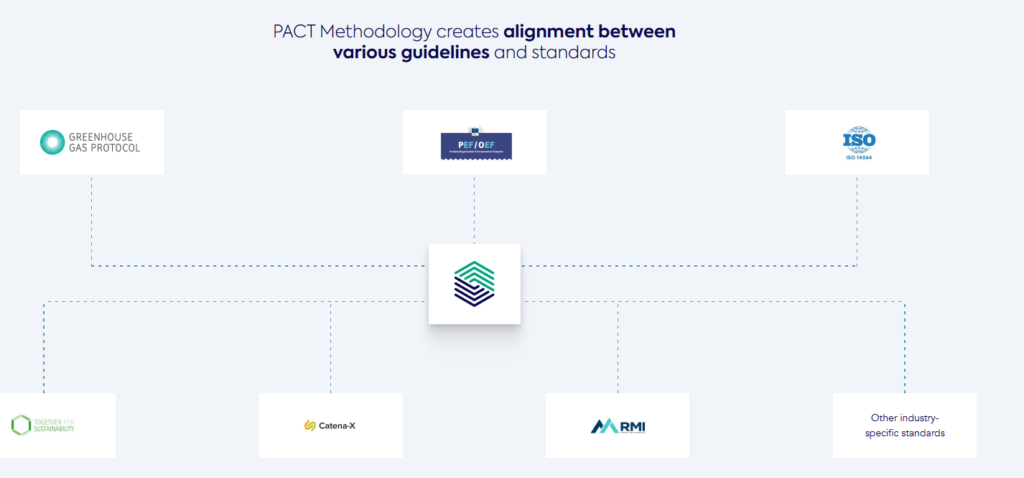

PACT is a neutral initiative convened by the World Business Council for Sustainable Development to help calculate product carbon footprints and implement consistent carbon footprint data exchange. The PACT methodology is industry and region agnostic, and designed to create alignment between many other GHG emissions guidelines and standards. By harmonizing upstream Scope 3 emissions, PACT hopes to integrate the global reporting ecosystem.

PACT is achieving this goal through two initiatives: the PACT methodology (formerly known as the Pathfinder Framework) guidelines and the Pathfinder Network data exchange infrastructure.

The PACT methodology is designed to help companies by ensuring that the PCF data they receive is consistent and reliable. It is built on existing frameworks and standards and guides accounting, verification, and exchange of cradle-to-gate PCFs. If every company in a value chain follows the Framework, the shared data should be granular, comparable, and accurate, all of which are necessary to drive effective decision making.

It includes the technical specifications for data exchange, but is a set of rules and standards, not a platform.

The Pathfinder Network is the data exchange infrastructure necessary to connect the PACT-complient PCFs, in their words “the common nexus for all organizations to connect seamlessly, exchange, and derive insights from emissions data.” Right now, the PACT network is a collection of third-party PCF data exchange solutions that are meet certain standards to be known as PACT-compliant.

What to Look For in a Product Carbon Footprint Solution and Carbon Footprint Data Exchange

Whatever system you’re using for carbon footprint data exchange, whether it’s Catena-X, Ouranos, TfS, or PACT, you’re going to need to calculate it first. PCF data collection and calculation is difficult, expensive, and time-consuming on your own, so you’re going to want a solution to help.

You should look for:

Integrated real data. Primary data derived directly from your production processes (including the ability to install submeters on your factory floor) gives you better decision making capabilities, future-proof compliance, and the ability to use that data to improve your processes.

Ability to monitor over time. Sustainability consultants show up, hand you a report and then are gone until the next engagement. And they aren’t cheap either. Get a solution that lets you measure and demonstrate improvement over time.

The right certifications. You’re going to want verified ISO 14067 certification, showing that the PCF is accurate and making compliance much simpler, and SOC 2 certification, showing that your provider is keeping your sensitive data safe.

Ease of use. PCF software balances accuracy and simplicity. Carbon accounting platforms often have slick UIs, but rely on default data. Professional grade PCF software is often byzantine in its complexity. Try to find a happy medium.

Want a software that ticks all the boxes? You’re already in the right place. The Glassdome Product Carbon Footprint platform is the first ISO 14067-verified PCF software platform, and it’s already used all over the world to calculate product carbon footprints based on real data.

Next up: Exchanging your PCF with the companies and regulators that need it.

Make sure your solution provider has the right technology and partnerships for seamless data exchange.

For example, Glassdome has secure, integrated data exchange functionality in our platform. We also have a partnership with Siemens SiGREEN, and we’re working toward a full technical integration. This will make data exchange even more streamlined in certain supply chains and regions.

It’s especially useful for companies that need to engage with Catena-X, as Siemens has been closely involved with its development from the start.

Find out if the most accurate real-data-based PCF solution is right for you

Talk to Glassdome sustainability expert